Maluso a CNC Machining Clamping

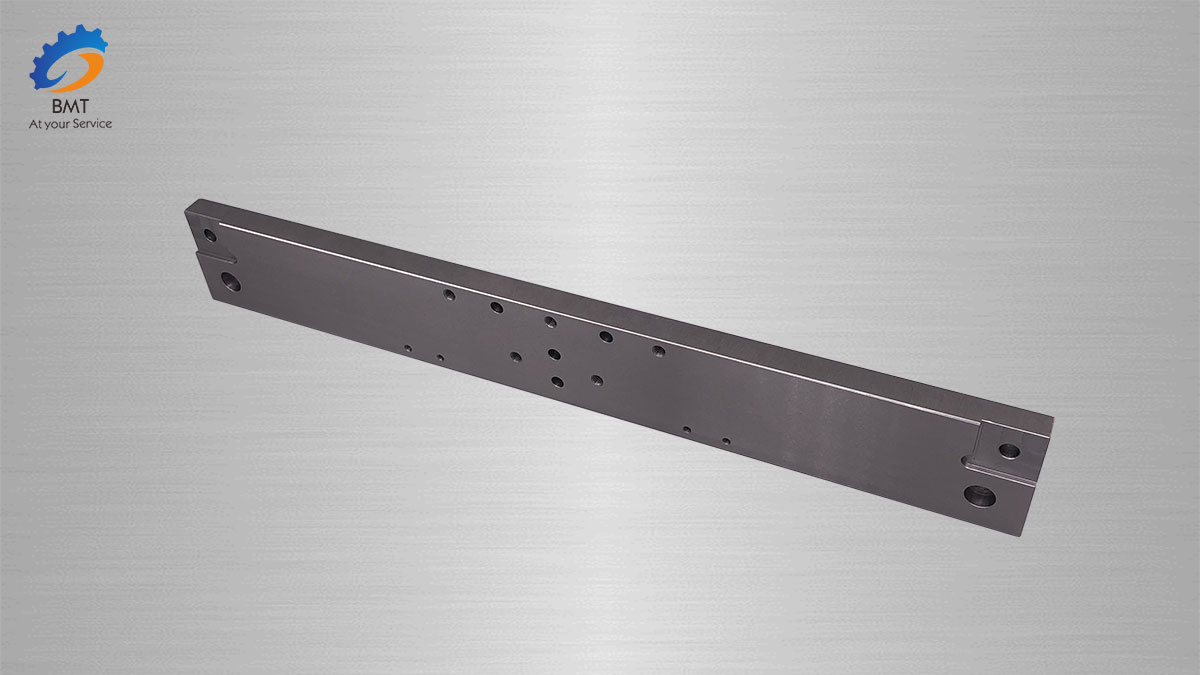

Machining Part Clamping:

Mfundo yofunikira ya pindani malo unsembe

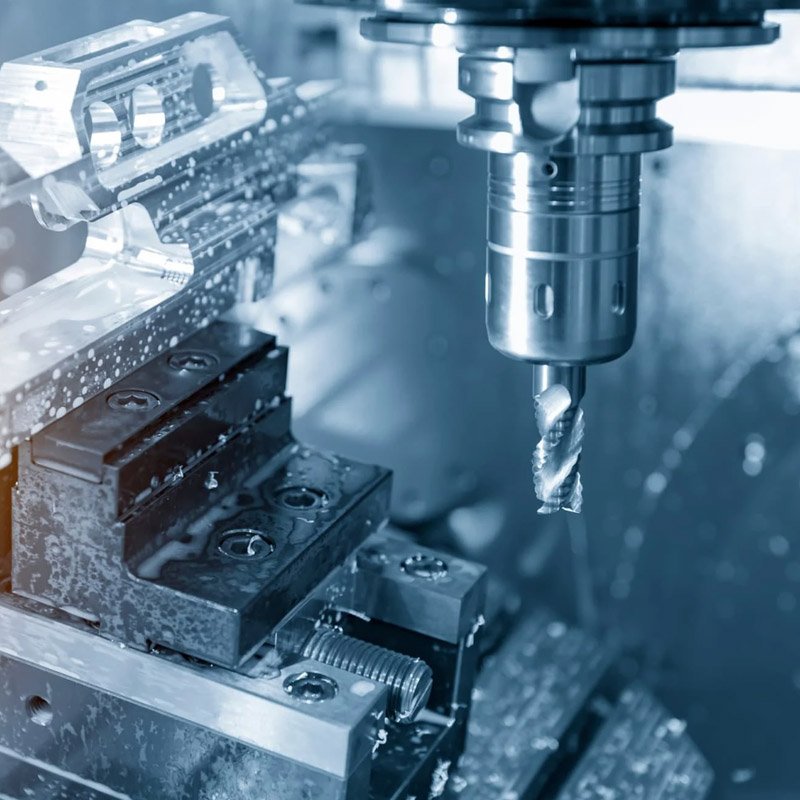

Mukakonza magawo pa chida cha makina a CNC, mfundo yayikulu yoyika ndikuyika ndikusankha malo oyenera komanso pulani yolumikizira. Samalani mfundo zotsatirazi posankha:

1. Yesetsani kukhala ndi benchmark yolumikizana pamapangidwe, machitidwe ndi mawerengedwe a mapulogalamu.

2. Chepetsani kuchuluka kwa nthawi zomangirira, ndipo konzani malo onse oti akonzere mutatha kuyika ndi kukanikiza kamodzi momwe mungathere.

3. Pewani kugwiritsa ntchito makina opangidwa ndi makina opangira makina kuti mupereke masewera olimbitsa thupi kuti agwiritse ntchito zida zamakina a CNC.

Mfundo zazikuluzikulu zopindika ndikusankha zomangira

Makhalidwe a CNC Machining amaika patsogolo zofunika ziwiri zofunika kwa fixture: chimodzi ndi kuonetsetsa kuti kugwirizana malangizo fixture ndi okhazikika ndi kugwirizana malangizo a chida makina; ina ndikugwirizanitsa kukula kwa ubale pakati pa zigawo ndi makina ogwirizanitsa dongosolo. Komanso, mfundo zotsatirazi ziyenera kuganiziridwa:

1. Pamene gulu la magawo silili lalikulu, ma modular fixtures, zosinthika zosinthika ndi zina zonse ziyenera kugwiritsidwa ntchito momwe zingathere kuti muchepetse nthawi yokonzekera kupanga ndikusunga ndalama zopangira.

2. Ingoganizirani kugwiritsa ntchito zida zapadera panthawi yopanga zinthu zambiri, ndipo yesetsani kukhala ndi dongosolo losavuta.

3. Kutsitsa ndi kutsitsa kwa magawo kuyenera kukhala kofulumira, kosavuta komanso kodalirika kufupikitsa nthawi yoyimitsa makina.

4. Zigawo zomwe zili pazitsulo siziyenera kulepheretsa makina a pamwamba pa zigawozo ndi chida cha makina, ndiko kuti, choyikapo chiyenera kutsegulidwa, ndipo malo ake ndi zigawo za clamping siziyenera kukhudza mpeni panthawi yokonza (monga kugunda. , ndi zina).

Kulakwitsa kwa makina

Kuphatikizika kwa zolakwika zowongolera manambala kumapangidwa ndi kusintha kolakwika kwa pulogalamu, makina olakwika a zida zamakina, cholakwika chokhazikika, chida cholakwika chokhazikitsa zida ndi zolakwika zina.

1. Vuto la pulogalamu limapangidwa ndi cholakwika δ ndi cholakwika chozungulira. Cholakwika chapafupifupi δ chimapangidwa poyandikira njira yokhotakhota yosazungulira yokhala ndi gawo lolunjika kapena gawo lozungulira, monga momwe tawonera pa Chithunzi 1.43. Cholakwika chozungulira ndi cholakwika chomwe chimapangidwa pozunguliza mtengo wolumikizira kumtengo wofanana ndi mphamvu panthawi yokonza deta. Kufanana kwa pulse kumatanthawuza kusuntha kwa chigawo chilichonse chogwirizana ndi axis coordinate. Zida zamakina a CNC mwachizolowezi nthawi zambiri zimakhala ndi kugunda kofanana ndi 0.01mm; zolondola kwambiri CNC makina zida zili ndi kugunda kwamtengo wofanana 0.005mm kapena 0.001mm, etc.

2. Cholakwika cha chida cha makina chimayambitsidwa ndi zolakwika za dongosolo la CNC ndi dongosolo la chakudya.

3. Cholakwika choyikirapo nthawi zonse chimayamba pomwe chogwirira ntchito chimayikidwa pazida ndipo chimayikidwa pa chida cha makina.

4. Chida chokhazikitsa cholakwika chida chimapangidwa pozindikira malo achibale a chidacho ndi chogwirira ntchito.