Maluso Osankha Zida a CNC Machining

Sankhani Zida za CNC Milling

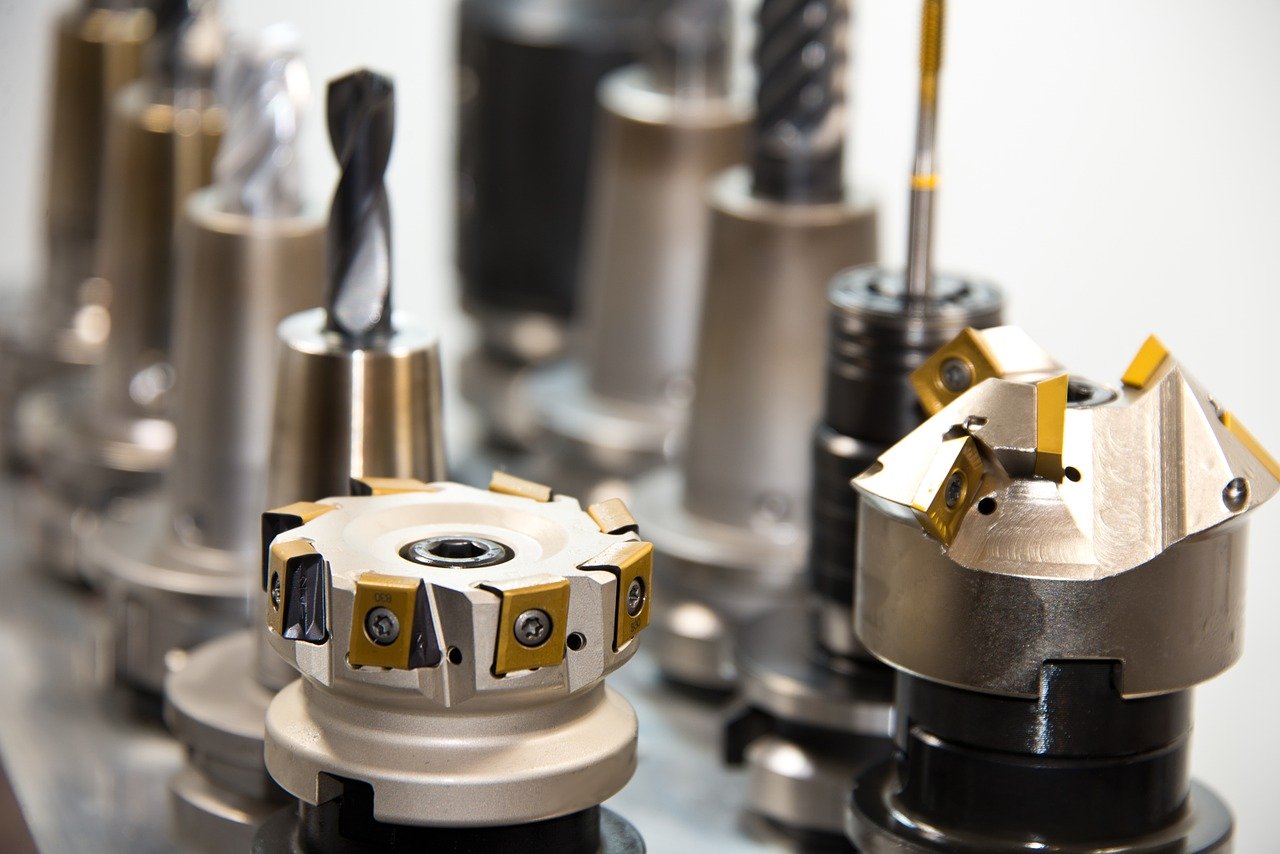

M'makina a CNC, mphero zokhala pansi zathyathyathya zimagwiritsidwa ntchito pogaya mkati ndi kunja kwa mbali za ndege ndi ndege yamphero. Zambiri zamagawo ofunikira a chipangizocho ndi motere: Choyamba, utali wozungulira wa chodulira mphero uyenera kukhala wocheperako kuposa utali wocheperako wa curvature Rmin wamkati wamkati wa gawolo, nthawi zambiri RD= (0.8-0.9) Rmin. . Chachiwiri ndi kutalika kwa gawo H <(1/4-1/6) RD kuonetsetsa kuti mpeni uli ndi mphamvu zokwanira. Chachitatu, pamene mphero pansi pa poyambira wamkati ndi lathyathyathya-bottomed mphero mapeto, chifukwa zidutsa ziwiri za poyambira pansi ayenera anapiringana, ndi utali wozungulira pansi m'mphepete mwa chida ndi Re = Rr, ndiko kuti, diameter ndi d=2Re=2(Rr), mukakonza Tengani utali wa chida monga Re=0.95 (Rr).

Pakukonza ma profiles ena a mbali zitatu ndi ma contour okhala ndi ma angles osinthika, ocheka mphero ozungulira, odula mphete, odula ng'oma, odulira mphero ndi ma disc mphero amagwiritsidwa ntchito. Pakadali pano, zida zambiri zamakina a CNC zimagwiritsa ntchito zida zokhazikika komanso zokhazikika. Pali miyezo yamayiko ndi mitundu yotsatiridwa ya omwe ali ndi zida ndi mitu ya zida monga zida zokhotakhota zakunja zamakina ndi zida zotembenuza nkhope. Kwa malo opangira makina ndi osinthira zida zodziwikiratu Zida zamakina zomwe zidayikidwa ndi zonyamula zida zasinthidwa ndikusinthidwa. Mwachitsanzo, code standard ya tapered shank tool system ndi TSG-JT, ndi code standard ya straight shank tool system ndi DSG-JZ. Kuphatikiza apo, pa chida chosankhidwa Musanagwiritse ntchito, ndikofunikira kuyeza kukula kwa chida kuti mupeze deta yolondola, ndipo wogwiritsa ntchitoyo amalowetsa zidziwitsozo mudongosolo la data, ndikumaliza kukonzanso kudzera pa kuyimba kwa pulogalamuyo, potero akukonza ma workpiece oyenerera. .

Folding Tool Point ndi Tool Change Point

Kodi chidacho chimayamba kusuntha kuchokera pamalo otani? Chifukwa chake kumayambiriro kwa pulogalamuyo, malo omwe chidacho chimayamba kuyenda munjira yolumikizira ntchito ziyenera kutsimikiziridwa. Udindo uwu ndiye poyambira chida chokhudzana ndi chogwirira ntchito pomwe pulogalamuyo ikuchitidwa. Chifukwa chake imatchedwa poyambira pulogalamu kapena poyambira. Malo oyambira awa nthawi zambiri amatsimikiziridwa ndi kuyika zida, chifukwa chake mfundoyi imatchedwanso kuti chida chokhazikitsa. Pokonza pulogalamuyo, malo a malo opangira zida ayenera kusankhidwa bwino. Mfundo yokhazikitsira zida ndikuthandizira kukonza manambala ndikusintha mapulogalamu.

N'zosavuta agwirizane ndi fufuzani pa processing; cholakwika pokonza anayambitsa ndi chochepa. Malo oyika zida amatha kukhazikitsidwa pamakina, pamakina kapena pamakina. Pofuna kukonza kulondola kwa makina a gawolo, malo oyika zida ayenera kukhazikitsidwa momwe angathere pagawo lofotokozera kapena ndondomeko. Pogwiritsa ntchito chida cha makina, malo ogwiritsira ntchito chida akhoza kuikidwa pa malo opangira zida pogwiritsa ntchito zida zopangira zida, ndiko kuti, zochitika za "chida cha malo" ndi "chida chokhazikitsa". Zomwe zimatchedwa "chida cha malo" zimatanthawuza malo osungiramo chida, ndipo malo omwe ali ndi chida chosinthira ndi nsonga ya chida kapena pakati pa chida cha arc.

Mphero yotsirizira-pansi-pansi ndi mphambano ya chida ndi pansi pa chida; mphero yomaliza ndiye pakati pa mpira, ndipo kubowola ndiye mfundo. Pogwiritsa ntchito makina opangira zida zamanja, kulondola kwachidacho kumakhala kochepa, ndipo mphamvu zake ndizochepa. Mafakitale ena amagwiritsa ntchito magalasi owonetsera zida, zida zoyika zida, zida zosinthira zida zokha, ndi zina zambiri kuti achepetse nthawi yokhazikitsa zida ndikuwongolera kulondola kwa zida. Chidacho chikafunika kusinthidwa panthawi yokonza, chida chosinthira chida chiyenera kufotokozedwa. Zomwe zimatchedwa "chida chosinthira" zimatanthawuza malo a chida pamene chikuzungulira kusintha chida. Malo osinthira chida ayenera kukhala kunja kwa chogwirira ntchito kapena chowongolera, ndipo chogwirira ntchito ndi magawo ena sayenera kukhudzidwa panthawi yakusintha kwa chida.

Nsonga za mtundu uwu wa chida chotembenuza chimapangidwa ndi mizere yayikulu ndi yachiwiri yodulira, monga zida 900 zokhota zamkati ndi zakunja, zida zokhotakhota kumanzere ndi kumanja, zida zokhotakhota (zodula) ndi zida zosiyanasiyana zakunja ndi zamkati. nsonga zazing'ono chamfers. Chida chotembenuza dzenje. Njira yosankhidwa ya magawo a geometric a chida chokhotakhota (makamaka ngodya ya geometric) imakhala yofanana ndi kutembenuka wamba, koma mawonekedwe a makina a CNC (monga njira yopangira makina, kusokoneza makina, ndi zina zotero) ziyenera kuganiziridwa mozama. , ndipo nsonga ya chida yokha iyenera kuonedwa ngati mphamvu.

Dziwani Mtengo Wodula

M'mapulogalamu a NC, wopanga mapulogalamu ayenera kudziwa kuchuluka kwa njira iliyonse ndikuilemba mu pulogalamuyo monga malangizo. Kudula magawo kumaphatikizapo liwiro la spindle, kuchuluka kwa kudula kumbuyo ndi liwiro la chakudya. Kwa njira zosiyanasiyana zogwirira ntchito, magawo osiyanasiyana odulidwa ayenera kusankhidwa. Mfundo masankhidwe a kuchuluka kudula ndi kuonetsetsa Machining kulondola ndi roughness pamwamba pa mbali, kupereka sewero lathunthu kwa kudula ntchito chida, kuonetsetsa wololera chida durability, ndi kupereka sewero lathunthu kwa ntchito ya makina chida kuti azipeza zokolola. ndi kuchepetsa ndalama.