Zida Kusankhidwa kwa CNC Machining

Mfundo Yosankha Zida za CNC

Moyo wa zida umagwirizana kwambiri ndi kudula voliyumu. Popanga magawo odulira, moyo wa zida zoyenera uyenera kusankhidwa poyamba, ndipo moyo wa zida zomveka uyenera kutsimikiziridwa molingana ndi cholinga chokhathamiritsa. Nthawi zambiri amagawidwa kukhala apamwamba kwambiri zokolola chida moyo ndi mtengo wotsika mtengo chida moyo, woyamba anatsimikiza molingana ndi cholinga cha osachepera limodzi chidutswa munthu maola, ndipo chotsirizira anatsimikiza malinga ndi cholinga cha otsika mtengo ndondomeko.

Posankha zida, mungaganizire mfundo zotsatirazi molingana ndi zovuta za chida, kupanga ndi kugaya ndalama. Moyo wa zida zovuta komanso zolondola kwambiri ziyenera kukhala zapamwamba kuposa zida zamtundu umodzi. Pazida zowongolera makina, chifukwa cha nthawi yayitali yosinthira chida, kuti apereke kusewera kwathunthu pakuchita kwake ndikuwongolera magwiridwe antchito, moyo wa chida ukhoza kusankhidwa kukhala wotsika, nthawi zambiri 15-30min. Kwa zida zambiri, zida zamakina zamakina ndi zida zopangira makina opangira zida zovuta, kusintha zida, ndikusintha zida, moyo wa chida uyenera kukhala wapamwamba, ndipo kudalirika kwa chida kuyenera kutsimikiziridwa makamaka.

Pamene zokolola za ndondomeko inayake mumsonkhanowu zimachepetsa kupititsa patsogolo kwa zokolola za msonkhano wonse, moyo wa zida za ndondomekoyi uyenera kusankhidwa mochepa. Pamene mtengo wa zomera zonse pa unit nthawi ya ndondomeko inayake ndi yaikulu, moyo wa chida uyeneranso kusankhidwa Pansi. Mukamaliza mbali zazikulu, kuti muwonetsetse kuti chiphaso chimodzi chatha, ndikupewa kusintha chida pakati pa kudula, moyo wa chida uyenera kutsimikiziridwa molingana ndi kulondola kwa gawolo ndi kuuma kwapamwamba. Poyerekeza ndi njira wamba makina chida processing, CNC Machining amaika patsogolo zofunika apamwamba zida kudula.

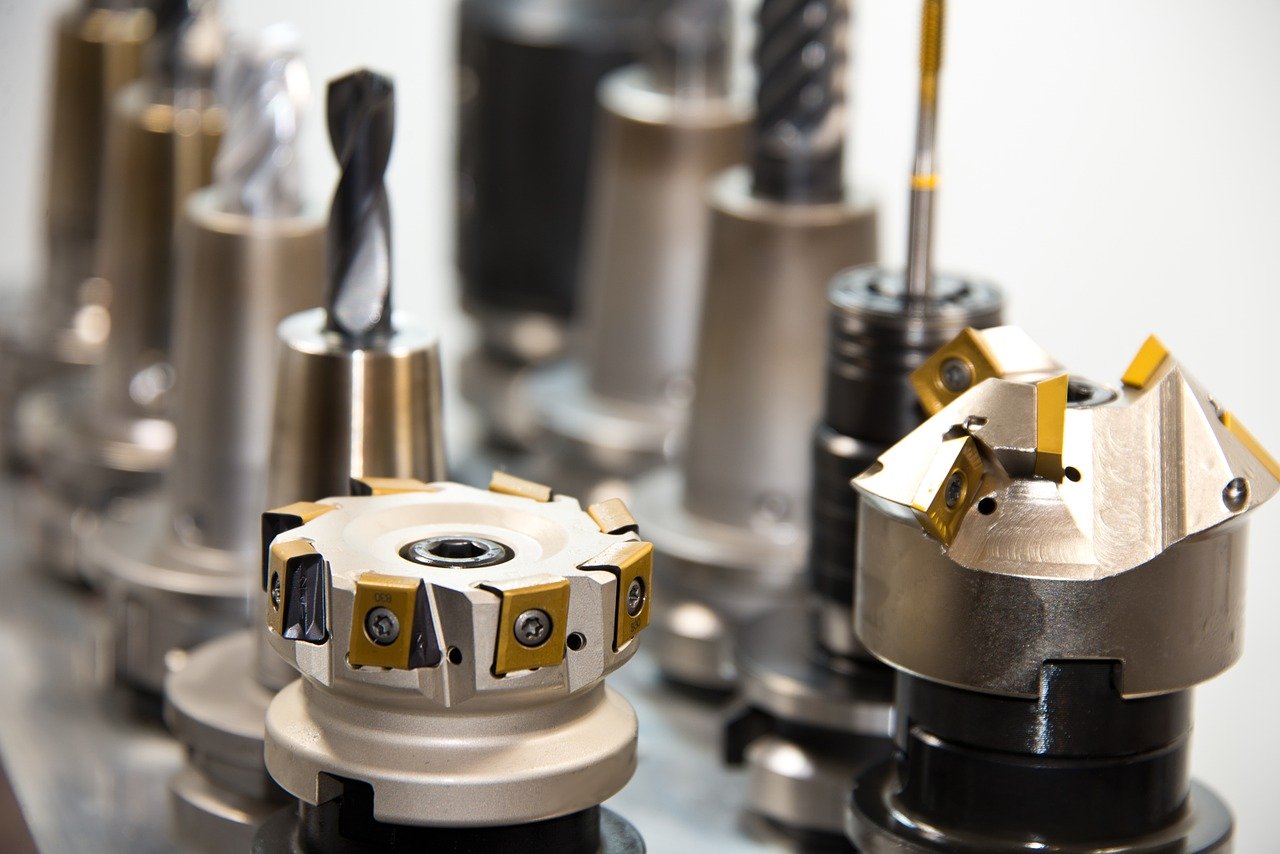

Sikuti zimangofunika khalidwe labwino komanso kulondola kwambiri, komanso zimafuna kukhazikika kwazithunzi, kukhazikika kwakukulu, komanso kuyika kosavuta ndi kusintha. Kukwaniritsa zofunikira zapamwamba za zida zamakina a CNC. Zida zosankhidwa pazida zamakina a CNC nthawi zambiri zimagwiritsa ntchito zida zoyenera kudula mothamanga kwambiri (monga chitsulo chothamanga kwambiri, ultra-fine-grained cemented carbide) ndikugwiritsa ntchito zolozera.

Sankhani Zida Zotembenuza CNC

Zomwe zimagwiritsidwa ntchito potembenuza CNC zidagawidwa m'mitundu itatu: zida zopangira, zida zoloza, zida za arc ndi mitundu itatu. Zida zosinthira zimatchedwanso zida zotembenuza za prototype, ndipo mawonekedwe a contour a magawo opangidwa ndi makina amatsimikiziridwa kwathunthu ndi mawonekedwe ndi kukula kwa m'mphepete mwa chida chotembenuza. Mu CNC kutembenuza zida, zida zosinthira wamba zimaphatikizapo zida zazing'ono zotembenuza ma radius arc, zida zokhotakhota zosakhala makokonana ndi zida zolumikizira. Mu makina a CNC, chida chosinthira chiyenera kugwiritsidwa ntchito pang'ono momwe mungathere kapena ayi. Chida chokhotakhota ndi chida chotembenuza chomwe chimadziwika ndi mzere wowongoka.

Nsonga za mtundu uwu wa chida chotembenuza chimapangidwa ndi mizere yayikulu ndi yachiwiri yodulira, monga zida 900 zokhota zamkati ndi zakunja, zida zokhotakhota kumanzere ndi kumanja, zida zokhotakhota (zodula) ndi zida zosiyanasiyana zakunja ndi zamkati. nsonga zazing'ono chamfers. Chida chotembenuza dzenje. Njira yosankhidwa ya magawo a geometric a chida chokhotakhota (makamaka ngodya ya geometric) imakhala yofanana ndi kutembenuka wamba, koma mawonekedwe a makina a CNC (monga njira yopangira makina, kusokoneza makina, ndi zina zotero) ziyenera kuganiziridwa mozama. , ndipo nsonga ya chida yokha iyenera kuonedwa ngati mphamvu.

Chachiwiri ndi chida chotembenuza chooneka ngati arc. Chida chotembenuza chopangidwa ndi arc ndi chida chotembenuza chomwe chimadziwika ndi mawonekedwe a arc okhala ndi chozungulira chaching'ono kapena cholakwika cha mbiri ya mzere. Mfundo iliyonse ya arc m'mphepete mwa chida chotembenuza ndi nsonga ya chida chotembenuza chofanana ndi arc. Chifukwa chake, malo opangira zida sali pa arc, koma pakatikati pa arc. Chida chotembenuza chooneka ngati arc chitha kugwiritsidwa ntchito potembenuza malo amkati ndi akunja, ndipo ndi oyenera kutembenuza mawonekedwe osiyanasiyana olumikizana bwino (concave). Posankha arc radius ya chida chotembenuza, ziyenera kuganiziridwa kuti arc radius yamphepete mwachitsulo chosinthira mfundo ziwiri iyenera kukhala yocheperapo kapena yofanana ndi utali wocheperako wokhotakhota pamtunda wa concave wa gawolo. kupewa processing dryness. Radiyo siyenera kusankhidwa yaying'ono kwambiri, apo ayi sizidzakhala zovuta kupanga, Chida chotembenuza chikhoza kuonongekanso chifukwa cha mphamvu yofooka ya nsonga ya chida kapena mphamvu yowononga kutentha kwa thupi la chida.