Zili bwanjiCNC Machiningkupita posachedwapa?

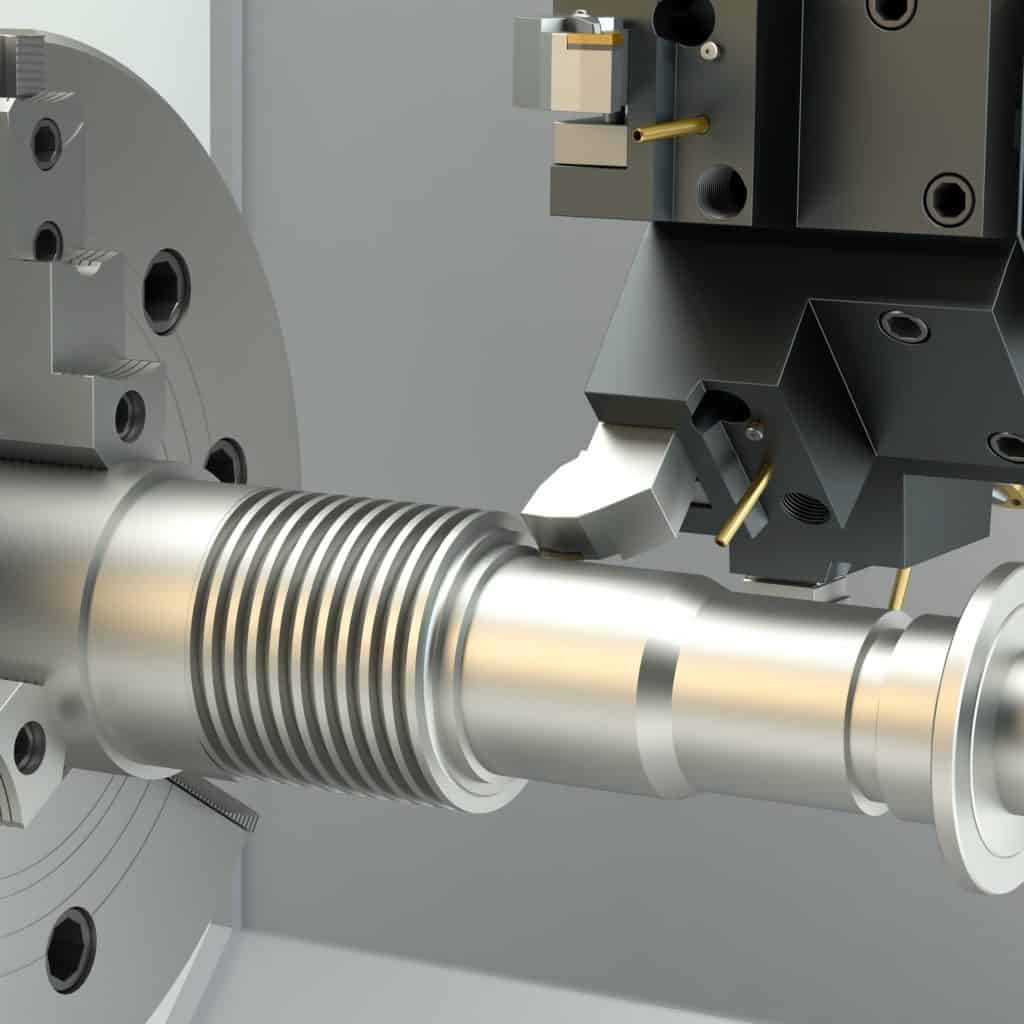

Pakali pano, pokonza mbali zolondola zamakina, zida zogwiritsira ntchito zitsulo zosapanga dzimbiri ndizitsulo zothamanga kwambiri komanso carbide yolimba. Zodula zitsulo zothamanga kwambiri ndizosavuta kupanga, zotsika mtengo, zakuthwa, komanso zimakhala zolimba, koma zimakhala zolimba kwambiri. Njira yopangira simenti yodula mphero ya carbide ndizovuta komanso zokwera mtengo, ndipo zimakhala bwino kukana kuvala pansi pamikhalidwe yodula kwambiri, zomwe zimathandizira kukhazikika kwa kulondola kwa magawo olondola azinthu zamakina.

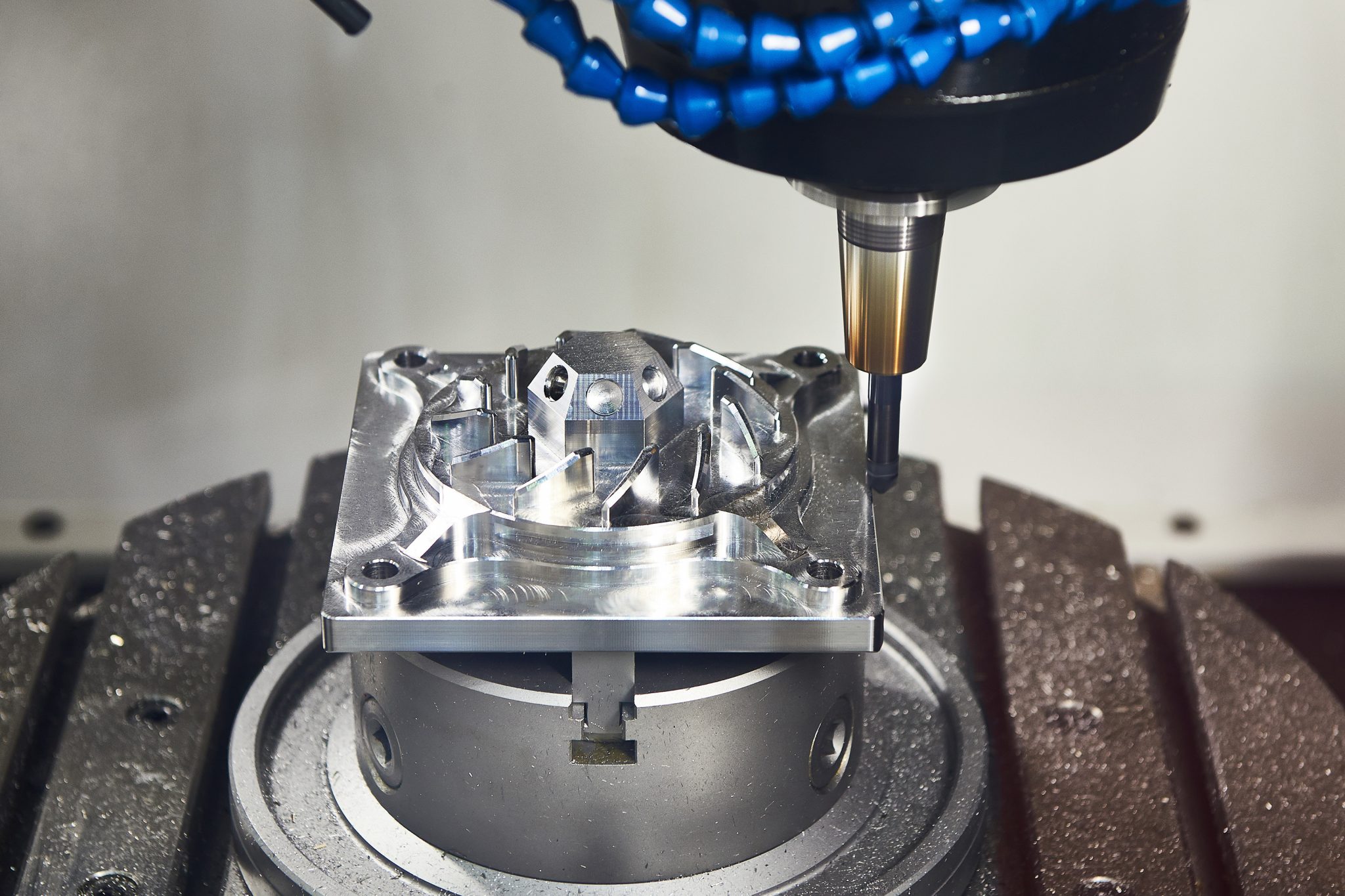

Poganizira za makhalidwe a CNC Machining ndi chuma kupanga, mfundo zotsatirazi zikhoza kutengedwa: ntchito mkulu-liwiro mkulu-liwiro zitsulo odula mphero kuti amalize, chifukwa masamba a mkulu-ntchito mkulu-liwiro zitsulo odula mphero ndi lakuthwa. Kupanga kwaukali kumafuna kutsika kolondola kwa zida, kukhazikitsa kosavuta kwa zida, nthawi yochepa yothandizira, komanso mtengo wotsika wopanga. Mukamaliza, gwiritsani ntchito mphero zapamwamba kwambiri zokutira carbide, zomwe zimatha kudula pa liwiro lalikulu ndikusunga makina olondola mosalekeza komanso okhazikika.mwatsatanetsatane mbali makina. Munthawi yabwinobwino, kumalizidwa kwa zinthu zambiri kapena mazana kumatha kumaliza.

Kusankha zida za geometrical magawo: Kusankha chida kuchokera pazomwe zilipo makamaka kumafunika kuganizira magawo a geometrical monga kuchuluka kwa mano, ngodya ya rake ndi blade helix angle. Pomaliza, tchipisi tachitsulo chosapanga dzimbiri sizovuta kupindika. Chida chokhala ndi mano ochepa komanso thumba lalikulu la chip chiyenera kusankhidwa kuti chipangitse kuchotsa chip kukhala chosalala komanso chopindulitsa pakukonza zitsulo zosapanga dzimbiri mwatsatanetsatane mbali zamakina.

Komabe, ngati ngodya yowongokayo ndi yayikulu kwambiri, imatha kufooketsa mphamvu ndi kukana kwa mphepete mwa chida. Nthawi zambiri, mphero yokhala ndi ngodya yabwinobwino ya madigiri 10-20 iyenera kusankhidwa. Ngodya ya helix imagwirizana kwambiri ndi angle yeniyeni ya chida. Pokonza chitsulo chosapanga dzimbiri, kugwiritsa ntchito chodulira chachikulu cha helix kumapangitsa kuti mphamvu yodulira ikhale yaying'ono.makina olondolandondomeko ndi Machining ndi khola.

Ubwino wa pamwamba pa workpiece ndi wapamwamba, ndipo mbali ya helix nthawi zambiri imakhala 35 ° -45 °. Chifukwa cha kusagwira bwino ntchito, kutentha kwakukulu komanso moyo waufupi wa zida zazitsulo zosapanga dzimbiri. Choncho, kudula kudya kwa mphero zosapanga dzimbiri kuyenera kukhala kotsika kusiyana ndi chitsulo wamba mpweya.

Kuziziritsa kokwanira ndi kudzoza kumatha kukulitsa moyo wa chida ndikuwongolera mawonekedwe amtundu wamakina olondola pambuyo pokonza. Pakupanga kwenikweni, mafuta apadera odulira zitsulo zosapanga dzimbiri amatha kusankhidwa ngati choziziritsa, ndipo ntchito yotulutsira madzi yapakatikati yopondereza kwambiri ya spindle ya chida cha makina imatha kusankhidwa. Mafuta odulira amawapopera pamalo odulira mothamanga kwambiri kuti azitha kuziziritsa mokakamiza ndi mafuta kuti azitha kuziziritsa komanso kudzoza.

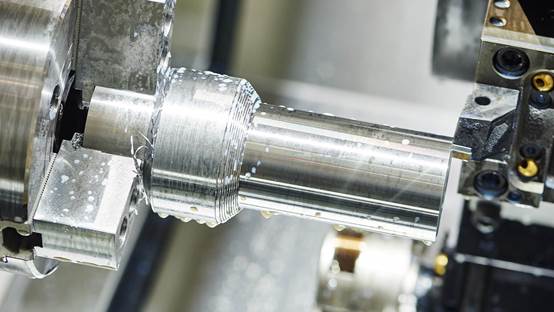

As makampani opanga makina olondolapitilizani kuwongolera kulondola kwa magawo ndi magawo, makina a CNC amatenga gawo lofunikira kwambiri pakupanga zonse, ndipo zida zochulukirachulukira za makina a CNC zimagulidwa, zomwe zimabweretsanso mndandanda wazovuta zomwe ziyenera kuthetsedwa mwachangu. . M'kati mwa kukonza magawo olondola a makina, zida zodulira, monga chida chofunikira chothandizira kutenga nawo gawo pantchito zopanga, zimagwira ntchito yayikulu pakupanga zida zamakina a CNC komanso kulondola komanso kulondola kwa magawo owongolera ndi kupanga, makamaka pakuwonjezeka. chiwerengero cha CNC makina zida. Pofuna kuthana ndi zovuta zomwe zimabweretsedwa ndi kasamalidwe kokhazikika, kukonza magwiridwe antchito am'magawo am'makina, ndikuchepetsa ndalama zogwirira ntchito, zida ndi zazikulu. Kenako, zida ziyenera kuyendetsedwa m'njira yapakati.

Nthawi yotumiza: Mar-15-2021