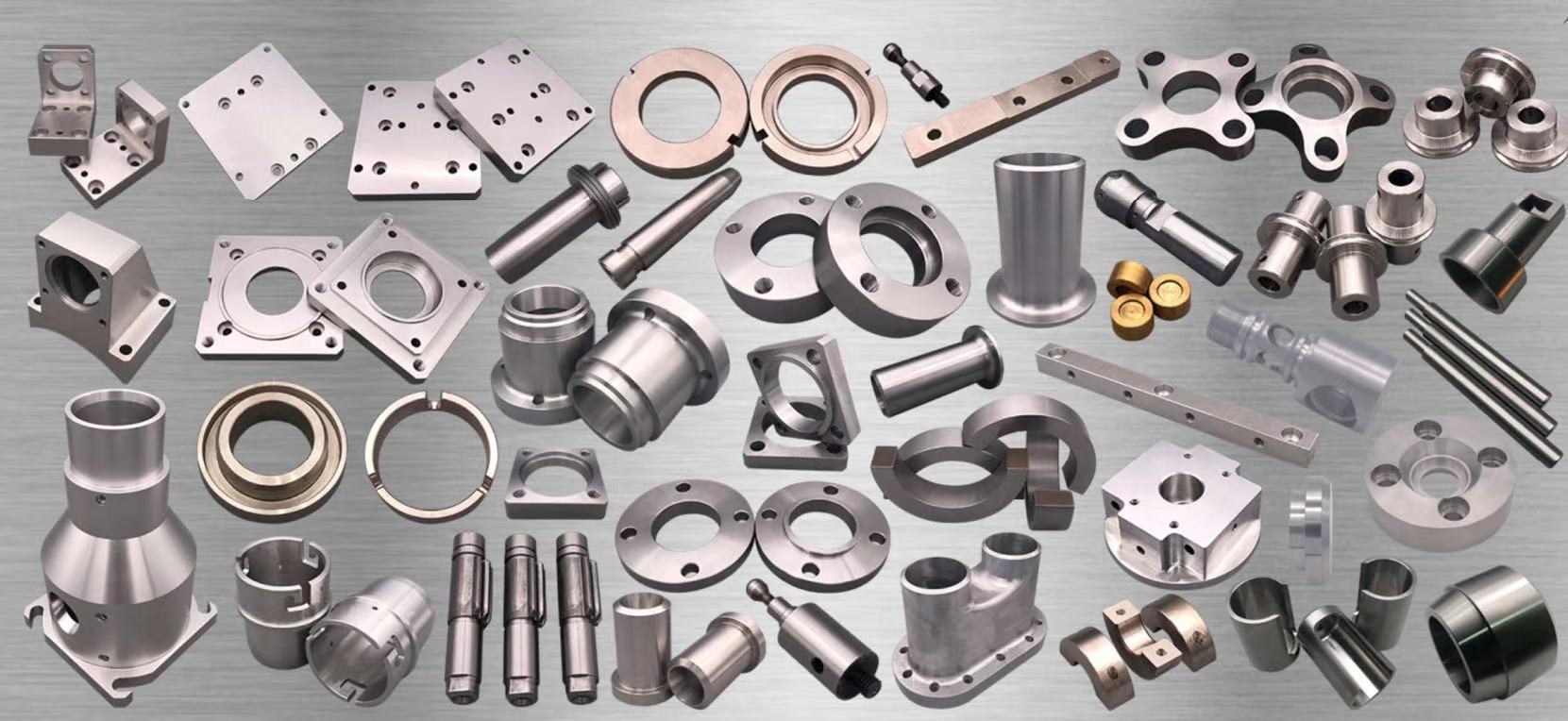

Zida zakumbuyo za fakitale, monga zida zamakina odulira zitsulo (kuphatikiza kutembenuza, mphero, kupanga, kuyika ndi zida zina), ngati zida zomwe zikufunika kuti zipange zidasweka ndipo ziyenera kukonzedwa, ziyenera kutumizidwa msonkhano makina kukonza kapena processing. Pofuna kuonetsetsa kuti ntchito ikupita patsogolo, mabizinesi ambiri amakhala ndi ma workshops, makamaka omwe ali ndi udindo wokonza zida zopangira.

Makina ochitira misonkhano amatha kugwiritsa ntchito CAD/CAM(kompyuta mothandizidwa ndi makina opanga makina opangira makina) kuti azingopanga zida zamakina a CNC. Ma geometry a magawo amasinthidwa okha kuchokera ku CAD system kupita ku CAM system, ndipo katswiri wamakina amasankha njira zosiyanasiyana zamakina pazithunzi zowonetsera. Pamene makina amasankha njira inayake yopangira, makina a CAD/CAM amatha kutulutsa kachidindo ka CNC, nthawi zambiri amatanthauza G code, ndipo code imalowetsedwa mu woyang'anira makina a CNC kuti agwire ntchitoyo.

Onse ogwira ntchito pamakina osiyanasiyana ayenera kuphunzitsidwa zaukadaulo wachitetezo ndikupambana mayeso asanayambe ntchito.

Asanayambe Opaleshoni

1. Musanagwire ntchito, gwiritsani ntchito mosamala zipangizo zotetezera malinga ndi malamulo, kumanga makapu, musavale scarves, magolovesi, akazi ayenera kuvala tsitsi mkati mwa chipewa. Woyendetsa ayenera kuyima pamapedali.

2. Maboti, malire oyendayenda, zizindikiro, chitetezo cha chitetezo (inshuwaransi) zipangizo, ziwalo zotumizira makina, mbali zamagetsi ndi malo opaka mafuta ziyenera kufufuzidwa mosamalitsa kuti zitsimikizire kudalirika musanayambe.

3. Mphamvu yotetezedwa yowunikira mitundu yonse ya zida zamakina siziyenera kupitilira 36 volts.

Mu Opaleshoni

1. Chida, clamp, cutter ndi workpiece ziyenera kumangidwa mwamphamvu. Mitundu yonse ya zida zamakina ziyenera kungokhala pa liwiro lotsika mukangoyamba, ndipo zitha kuyendetsedwa mwalamulo pokhapokha zonse zitakhala zachilendo.

2. Zida ndi zinthu zina ndizoletsedwa pamtunda wa njanji ndi tebulo logwira ntchito la chida cha makina. Osagwiritsa ntchito manja kuchotsa zosefera zachitsulo, ayenera kugwiritsa ntchito zida zapadera kuyeretsa.

3. Yang'anani mphamvu zozungulira makina musanayambe makinawo. Mukayamba makinawo, yimani pamalo otetezeka kuti mupewe magawo osuntha a

4. Pogwiritsa ntchito mitundu yonse ya zida zamakina, ndizoletsedwa kusintha njira yosinthira liwiro kapena sitiroko, kukhudza gawo lopatsira, kusuntha workpiece, chida chodulira ndi malo ena ogwirira ntchito pokonza, kuyeza kukula kulikonse mukugwira ntchito, ndi kusamutsa kapena kutenga zida ndi zinthu zina kudutsa gawo kufala kwa makina zida.

5. Phokoso lachilendo likapezeka, makinawo ayenera kuyimitsidwa kuti akonzere nthawi yomweyo. Sichiloledwa kugwira ntchito mokakamiza kapena ndi matenda, ndipo makinawo saloledwa kugwiritsa ntchito mochulukira.

6. Pakukonza gawo lililonse la makina, tsatirani mosamalitsa ndondomeko ya ndondomekoyi, muwone zojambula bwino, onani mfundo zolamulira za gawo lililonse, roughness ndi zofunikira zaumisiri za zigawo zofunikira, ndikudziwitsani ndondomeko yopangira gawo lopangira.

7. Imitsani makina pamene mukusintha liwiro ndi sitiroko ya chida cha makina, clamping workpiece ndi chida chodulira, ndikupukuta chida cha makina. Osasiya malo ogwirira ntchito pamene makina akugwira ntchito, yimitsani makinawo ndikudula magetsi.

Pambuyo pa Opaleshoni

1. Zida zopangira, zomalizidwa, zomalizidwa pang'ono ndi zinyalala ziyenera kuikidwa m'malo osankhidwa, ndipo zida zamitundu yonse ndi zida zodulira ziyenera kusungidwa bwino.

2. Pambuyo pa ntchito, magetsi ayenera kudulidwa, zida zodulira zichotsedwa, zogwirira ntchito za gawo lililonse zimayikidwa m'malo osalowerera ndale, ndi bokosi losinthira lotsekedwa.

3. Tsukani zida, yeretsani zidutswa zachitsulo, ndipo mudzaze njanji ndi mafuta opaka kuti zisawonongeke.

Nthawi yotumiza: Nov-29-2021