Wopanga Machining Wanu Wolondola

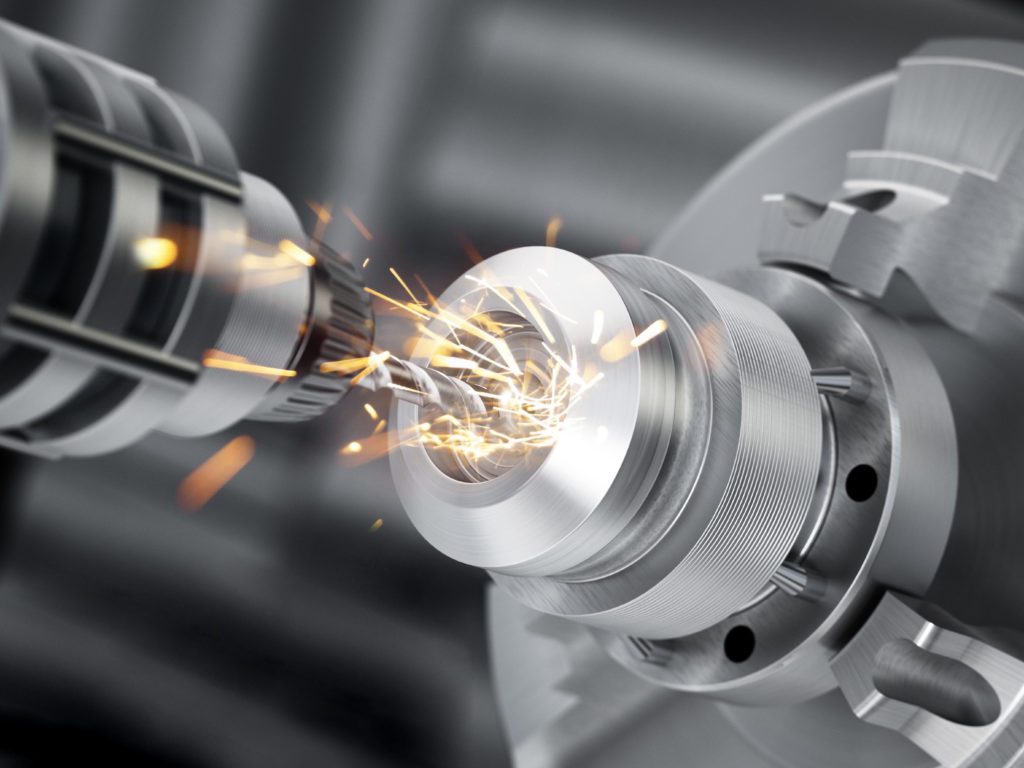

PRECISION MACHINING

Kukonzekera kolondola ndi njira yomwe mawonekedwe kapena magwiridwe antchito amasinthidwa ndi makina opangira. Malinga ndi kutentha kwa workpiece kuti kukonzedwa, izo zimagawidwa mu ozizira processing ndi kutentha processing. Nthawi zambiri, processing firiji, ndipo sayambitsa kusintha kwa mankhwala kapena gawo la workpiece, amatchedwa ozizira processing. Nthawi zambiri, kukonza kwapamwamba kapena kutsika kuposa kutentha kwanthawi zonse kumapangitsa kusintha kwa mankhwala kapena gawo la chogwiriracho, chomwe chimatchedwa matenthedwe. Cold processing akhoza kugawidwa mu kudula processing ndi kuthamanga processing malinga ndi kusiyana njira processing. Kutentha kwamafuta kumaphatikizapo chithandizo cha kutentha, kupangira, kuponyera ndi kuwotcherera.

Makina opangira magawo agalimoto ndi gawo lomwe limapanga magawo onse agalimoto ndi zinthu zomwe zimagwiritsidwa ntchito pokonza zida zamagalimoto. Monga maziko amakampani opanga magalimoto, zida zamagalimoto ndizofunikira kuti zithandizire chitukuko chokhazikika komanso chathanzi chamakampani opanga magalimoto. Makamaka, chitukuko chodziyimira pawokha komanso zatsopano zamagalimoto zamagalimoto zomwe zikuchitika mwamphamvu komanso mwachangu zimafunikira magawo amphamvu kuti athandizire. Mitundu yodziyimira payokha yamagalimoto ndi luso laukadaulo limafunikira magawo ndi zigawo monga maziko, ndipo kusinthika kodziyimira pawokha kwa magawo ndi zigawo kumakhala ndi mphamvu yoyendetsera ntchito yopanga magalimoto. Iwo amakhudza ndi kucheza wina ndi mzake. Palibe mtundu wodziyimira pawokha wa magalimoto athunthu, komanso magawo amphamvu. R&D ndi luso laukadaulo la kampaniyo ndizovuta kuphulika, ndipo popanda kuthandizidwa ndi gawo lolimba lazinthu, zidzakhala zovuta kuti mitundu yodziyimira pawokha ikhale yayikulu komanso yamphamvu.

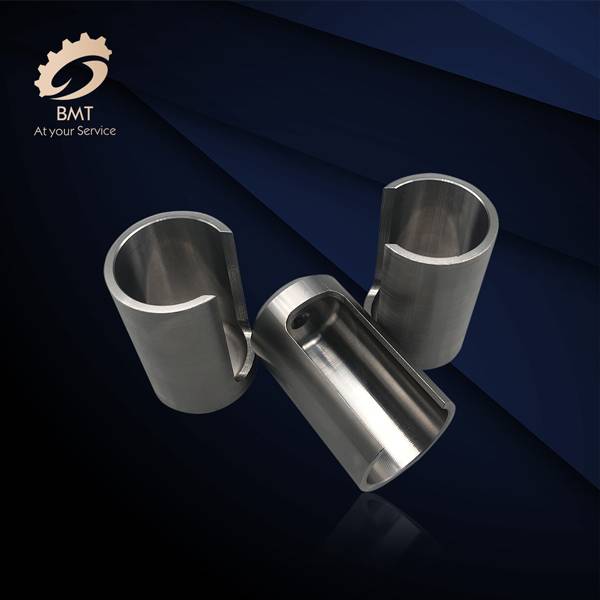

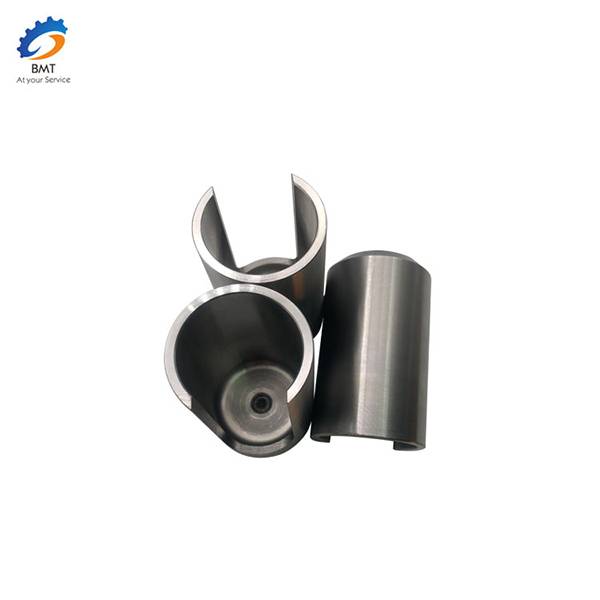

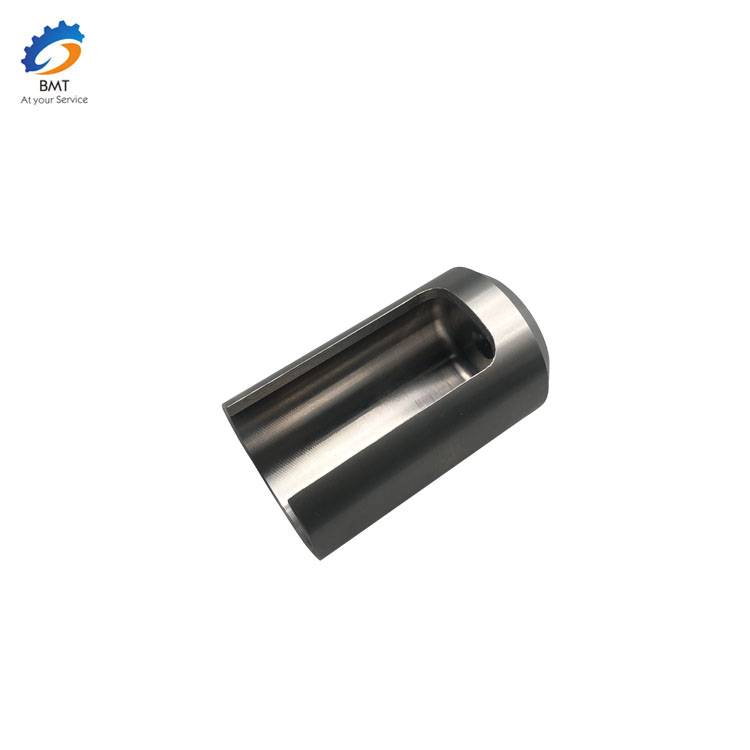

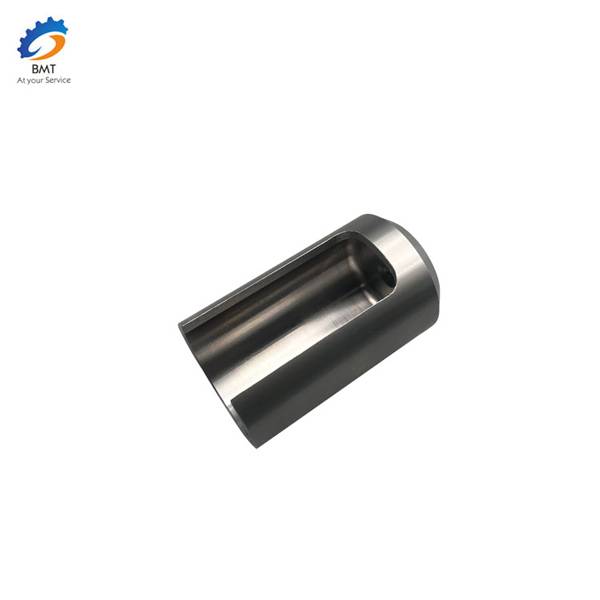

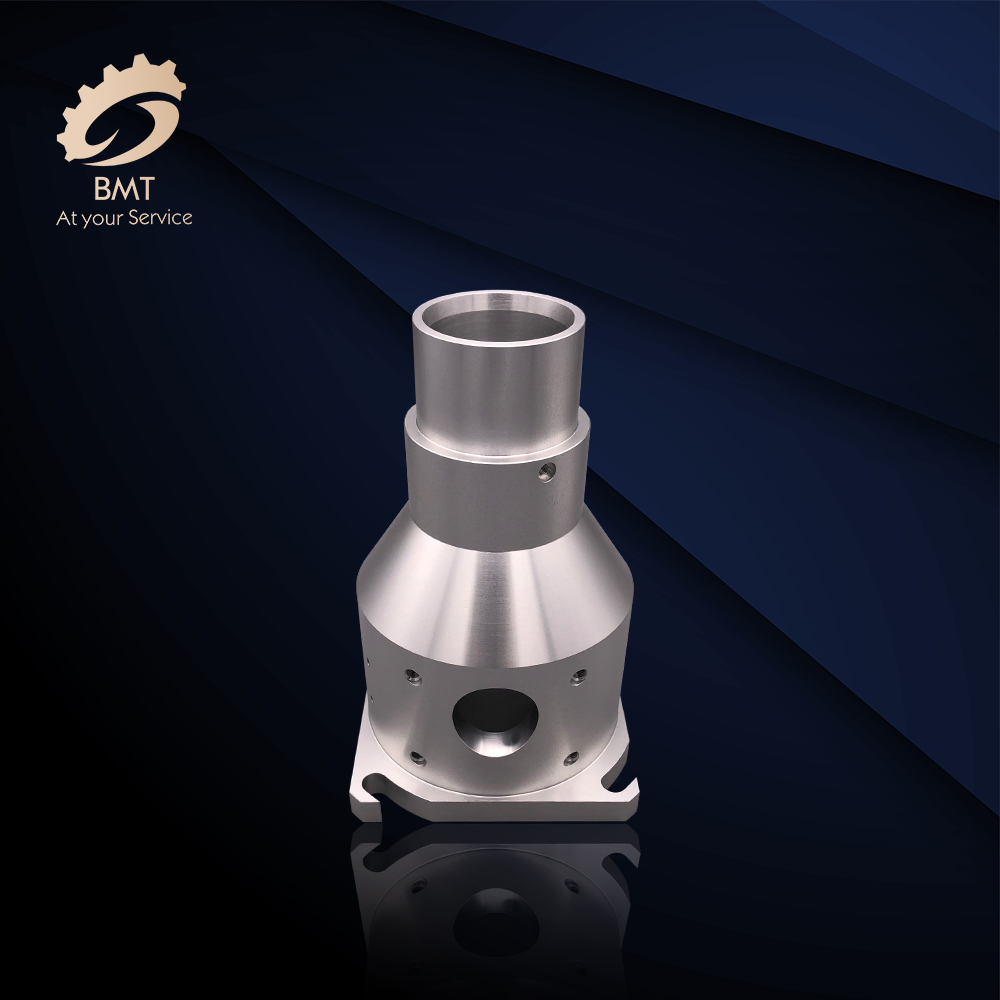

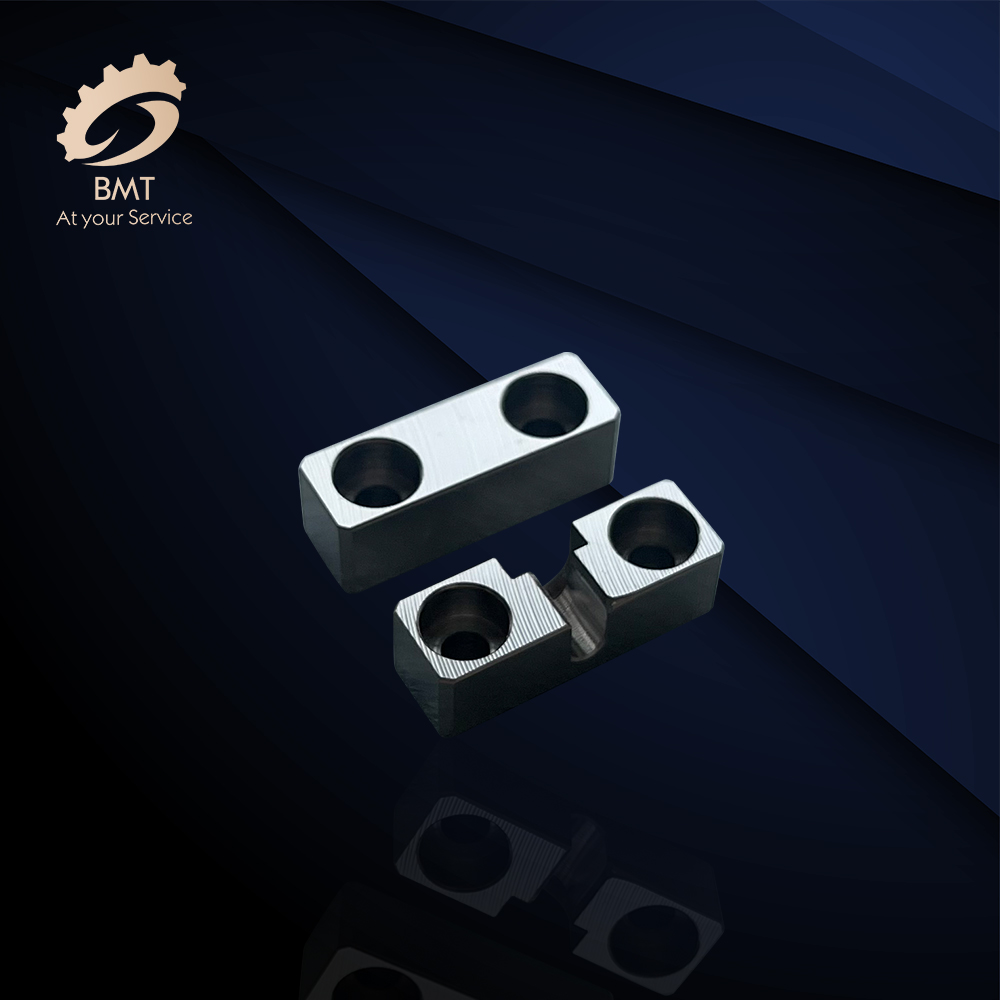

Magawo amatanthauza magawo omwe sangathe kulekanitsidwa ndi makina. Ndiwo zigawo zoyambira zamakina ndi gawo loyambira pamakina opanga makina. Kupanga nthawi zambiri sikufuna kusonkhana. Monga manja, tchire, mtedza, crankshafts, masamba, magiya, makamera, matupi olumikizira ndodo, mitu yolumikizira ndodo, ndi zina. Kwa makina athu olondola, kukonza ndizovuta kwambiri, ndipo njira zogwirira ntchito zimaphatikizapo kudula mkati ndi kunja. Pali zofunikira zenizeni za kukula ndi kulondola, monga 1mm kuphatikiza kapena minus micrometers, etc. Ngati kukula kwake kuli kwakukulu, kudzawonongeka. Panthawiyi, ndizofanana ndi kukonzanso, kuwononga nthawi komanso kuvutitsa, ndipo nthawi zina ngakhale zinthu zonse zomwe zakonzedwa zimachotsedwa. Izi zapangitsa kuti mtengo uwonjezeke, ndipo panthawi imodzimodziyo, mbalizo ndizosagwiritsidwa ntchito.

Zida zina wamba sizimatha kumaliza kukonza nkhungu, monga zibowo zokhala ndi ngodya zazing'ono za R; ma electrode amapangidwa ndi mphamvu yamagetsi. Izi nthawi zambiri zimapangidwa ndi mkuwa kapena graphite. Kukula kofulumira kwaukadaulo wopanga nkhungu kwakhala gawo lofunikira laukadaulo wamakono wopanga. Ukadaulo wamakono wopangira nkhungu ukupita patsogolo kuti upititse patsogolo chidziwitso, kuwongolera kusinthasintha kwa kupanga, kupanga agile ndi kuphatikiza dongosolo. Imawonetseredwa mwachindunji muukadaulo wa CAD/CAM wa nkhungu, ukadaulo waposachedwa wa laser wa nkhungu, ukadaulo wopangidwa mwaluso wa nkhungu, ndi ukadaulo wopitilira muyeso wa nkhungu. Mapangidwe a nkhungu amagwiritsa ntchito njira yotsirizira komanso njira yopangira malire kuti azitha kuyenda, kuziziritsa komanso kusamutsa kutentha. Ukadaulo woyeserera wamphamvu, ukadaulo wa CIMS wa nkhungu, matekinoloje apamwamba opanga monga ukadaulo wa nkhungu wa DNM ndiukadaulo wowongolera manambala apangidwa.