CNC Operating Mechanism

Onetsetsani bwinomakina chidamusanayambe, kuphatikizapo kuyendera makina opangira ntchito, zipangizo zamagetsi, maginito chuck ndi zina. Pambuyo poyendera, mafuta. Pambuyo pa mafuta, yesani kuyesa ndikutsimikizira kuti zonse zili bwino musanagwiritse ntchito. Pamene clamping workpiece, tcherani khutu mayanidwe ake ndi clamping.

Chidutswa chotayirira panthawi yopera chidzabweretsa zowopsa monga kuwulukira, kuvulaza anthu kapena kuphwanya gudumu lopera. Mukayamba kugwira ntchito, gwiritsani ntchito kusintha kwamanja kuti gudumu lopera likhale pafupi ndi workpiece. Chakudya choyambira chiyenera kukhala chaching'ono, ndipo mphamvu zambiri siziloledwa kuteteza gudumu lopera kuti lisagundane. Pakafunika kuwongolera kusinthasintha kwa benchi yogwirira ntchito ndi choyimitsa, iyenera kusinthidwa molondola malinga ndikugayakutalika kwa chogwiriracho, ndipo chotchingacho chizikhala chokhazikika.

Posintha gudumu lopera, mawonekedwewo ayenera kuyang'aniridwa poyamba kuti awone ngati pali kuwonongeka, ndiyeno gudumu lopera lidzagwedezeka ndi nyundo yamatabwa kapena ndodo. Phokoso lizikhala lomveka bwino popanda ming'alu. Mukayika gudumu lopera, liyenera kusonkhanitsidwa molingana ndi njira ndi zofunikira zomwe zafotokozedwa. Pambuyo pa static balancekutumiza, idzakhazikitsidwa ndi kuyesedwa. Itha kugwiritsidwa ntchito zonse zitakhala zachilendo.

Ogwira ntchito azivala magalasi otetezera panthawi ya ntchito, ndipo gudumu lopera liyenera kudulidwa moyenera kuti zisawonongeke. Yezerani chogwirira ntchito, sinthani kapena pukutani chida cha makina mukatha kuzimitsa. Mukamagwiritsa ntchito maginito chuck, disk pamwamba ndi workpiece ayenera kupukuta, kumangirizidwa ndi kuyamwa mwamphamvu.

Ngati ndi kotheka, choyimitsa chikhoza kuwonjezeredwa kuti chitetezeworkpiecekuchokera kusuntha kapena kuwuluka. Chisamaliro chidzaperekedwa pakuyika chivundikiro chotetezera cha gudumu lopera kapena chotchinga cha chida cha makina, ndipo mbali ya siteshoni idzazungulira kutsogolo kwa gudumu lopera mofulumira kwambiri.

Titumizireni uthenga wanu:

-

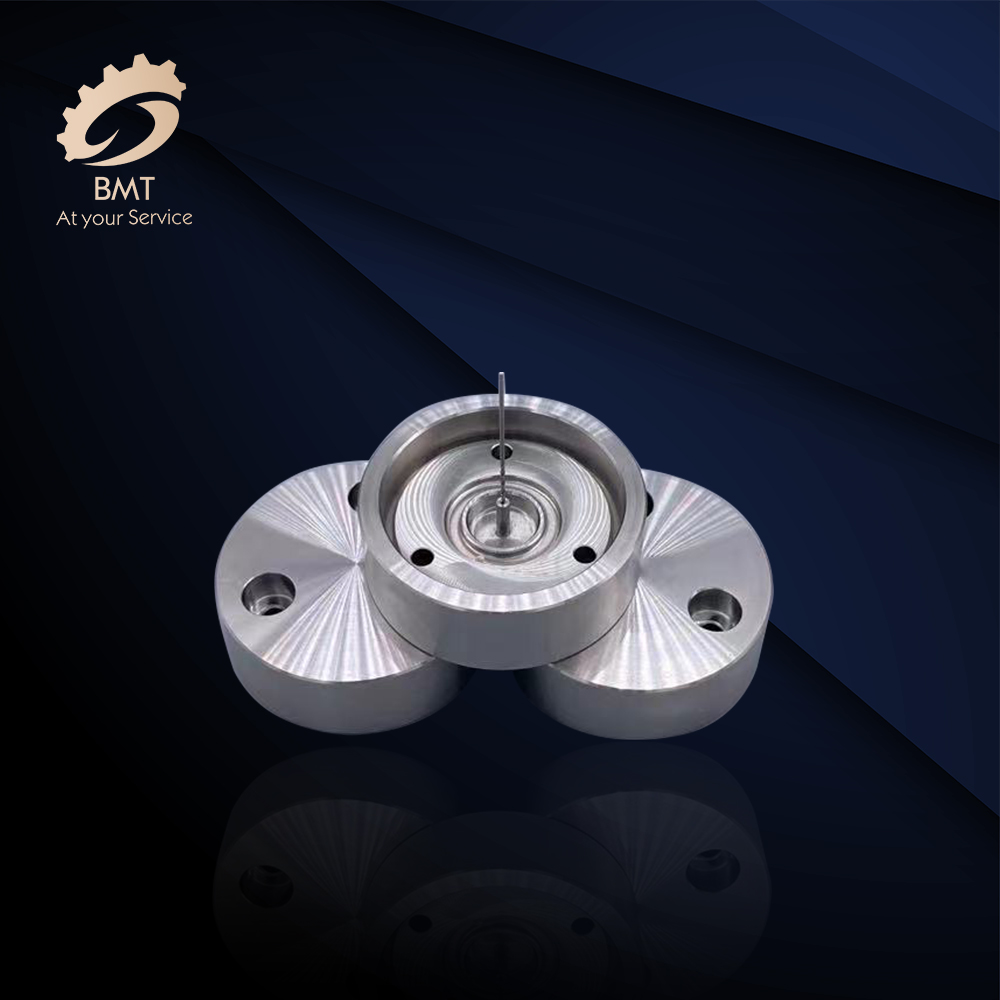

Aluminium CNC Machining Parts

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

Zida Zopangidwa ndi CNC ku Italy

-

CNC Machining Aluminium Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Zida za Titanium ndi Titanium Alloy

-

Titaniyamu ndi Titanium Alloy Forgings

-

Titaniyamu ndi Titanium Alloy Waya

-

Mipiringidzo ya Titaniyamu

-

Titaniyamu Mipope/Machubu Opanda Msokonezo

-

Titaniyamu Welded mapaipi/machubu