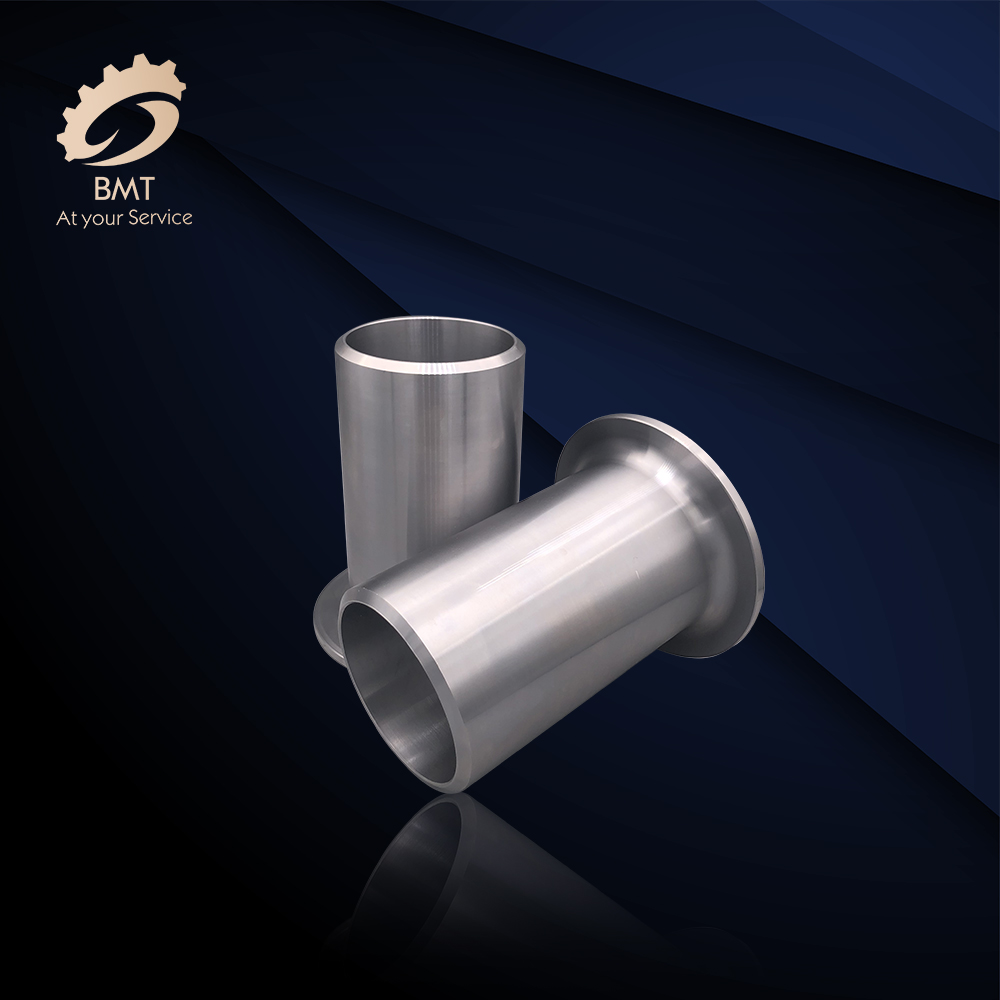

Titanium Alloy CNC Machining

Pamene kuuma kwa titaniyamu alloy ndi kwakukulu kuposa HB350, kudula kumakhala kovuta kwambiri, ndipo pamene kuli kochepa kuposa HB300, kumakhala kosavuta kumamatira ku mpeni ndipo kumakhala kovuta kudula. Choncho, vuto la titaniyamu likhoza kuthetsedwa kuchokera pa tsamba. Kuvala kwa groove mu makina a titaniyamu kumavala kumbuyo ndi kutsogolo kutsogolo kwakuya kwa kudula, komwe nthawi zambiri kumachitika chifukwa cha kusanjikiza kouma komwe kumasiyidwa ndi makina apitawo.

The mankhwala anachita ndi kufalikira kwa chida ndi workpiece zakuthupi pa processing kutentha oposa 800 °C ndi chimodzi mwa zifukwa mapangidwe poyambira kuvala. Chifukwa pakupanga makina, mamolekyu a titaniyamu a workpiece amadziunjikira kutsogolo kwa tsamba ndipo "amawotcherera" pamphepete mwa tsamba pansi pa kuthamanga kwambiri ndi kutentha kwakukulu, kupanga m'mphepete mwake.

Pamene anamanga m'mphepete peels pa odula m'mphepete, amachotsa ❖ kuyanika carbide amaikapo, kotero machining titaniyamu kumafuna zipangizo amaika wapadera ndi geometries.

.

Ndikoyenera kutchula kuti popeza ma aloyi a titaniyamu amapanga kutentha kwakukulu panthawi yokonza, kuchuluka kwamadzimadzi odula kwambiri ayenera kupopera pamphepete mwa nthawi yake komanso molondola kuti achotse kutentha. Palinso mawonekedwe apadera a odula mphero omwe amagwiritsidwa ntchito makamaka pokonza titaniyamu alloy pamsika masiku ano, omwe ali oyenera kukonza titaniyamu alloy.

Pakalipano, mayiko onse akupanga ma aloyi atsopano a titaniyamu omwe ali ndi mtengo wotsika komanso wokwera mtengo, ndipo amayesetsa kupanga titaniyamu kuti alowe m'munda wamakampani omwe ali ndi msika waukulu kwambiri. dziko langa limayesetsanso kupita patsogolo m'munda uno.

Amakhulupirira kuti chifukwa cha kuyesetsa kwa akatswiri onse amakampani, kukonza ma aloyi a titaniyamu sikudzakhalanso vuto m'tsogolomu, koma kudzakhala tsamba lakuthwa pakukula kwamakampani opanga dziko langa, kuthana ndi zopinga za chitukuko cha dziko langa. makampani onse.

Titumizireni uthenga wanu:

-

Aluminium CNC Machining Parts

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

Zida Zopangidwa ndi CNC ku Italy

-

CNC Machining Aluminium Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Zida za Titanium ndi Titanium Alloy

-

Titaniyamu ndi Titanium Alloy Forgings

-

Titaniyamu ndi Titanium Alloy Waya

-

Mipiringidzo ya Titaniyamu

-

Titaniyamu Mipope/Machubu Opanda Msokonezo

-

Titaniyamu Welded mapaipi/machubu