Titaniyamu ndi Titanium Alloy Forgings

Titaniyamu ndi titaniyamu aloyi ndi ubwino otsika kachulukidwe, mkulu yeniyeni mphamvu ndi kukana dzimbiri zabwino, ndipo chimagwiritsidwa ntchito m'madera osiyanasiyana.

Kupanga kwa Titaniyamu ndi njira yopangira yomwe imagwiritsa ntchito mphamvu yakunja ku zitsulo za titaniyamu (Kupatulapo mbale) kuti apange mapindikidwe apulasitiki, kusintha kukula, mawonekedwe, ndikusintha magwiridwe antchito. Amagwiritsidwa ntchito popanga zida zamakina, zogwirira ntchito, zida kapena zopanda kanthu. Komanso, malinga ndi kayendedwe ka slider ndi ofukula ndi yopingasa kayendedwe ka slider (Pa forging wa slider mbali, mafuta ndi kuzirala, ndi kupanga magawo mkulu-liwiro kupanga), mayendedwe ena akhoza ziwonjezeke ndi pogwiritsa ntchito chipangizo cholipirira.

Njira zomwe zili pamwambazi ndizosiyana, ndipo mphamvu yopangira mphamvu yofunikira, njira, kuchuluka kwa zinthu zomwe zimagwiritsidwa ntchito, zotulutsa, kulolerana kwazithunzi, ndi mafuta ndi njira zoziziritsa ndizosiyana. Izinso ndi zinthu zomwe zimakhudza mlingo wa automation.

Kupanga ndi njira yogwiritsira ntchito pulasitiki yachitsulo kuti mupeze njira yopangira pulasitiki yokhala ndi mawonekedwe enaake komanso mawonekedwe osokonekera potengera kapena kukakamizidwa kwa chida. Kupambana kwa kupanga kupanga ndikuti sikungopeza mawonekedwe a magawo amakina, komanso kuwongolera mawonekedwe amkati azinthu ndikuwongolera mawonekedwe amakanika a magawo amakina.

1. Kupanga Kwaulere

Kupanga kwaulere kumachitika pakati pa mafelemu awiri kapena nkhungu popanda patsekeke. Zida zomwe zimagwiritsidwa ntchito popanga zaulere ndizosavuta mawonekedwe, zosinthika, zazifupi popanga komanso zotsika mtengo. Komabe, kulimba kwa ntchito ndikwambiri, ntchitoyo ndi yovuta, zokolola ndizochepa, mtundu wa forgings siwokwera, ndipo machining allowance ndi akulu. Choncho, ndizoyenera kugwiritsidwa ntchito pokhapokha ngati palibe zofunikira zapadera pa ntchito ya ziwalozo ndipo chiwerengero cha zidutswa ndizochepa.

2. Open Die Forging (Die Forging with Burrs)

Chopandacho chimakhala chopunduka pakati pa ma module awiri okhala ndi ma cavities olembedwa, kupangirako kumangotsekeredwa mkati, ndipo chitsulo chowonjezera chimatuluka kuchokera pampata wopapatiza pakati pa awiriwo amafa, ndikupanga ma burrs mozungulira. Pansi pa kukana kwa nkhungu ndi zozungulira zozungulira, zitsulo zimakakamizika kukanikizidwa mu mawonekedwe a nkhungu.

3. Closed Die Forging (Die Forging popanda Burrs)

Panthawi yotsekera yotseka, palibe ma burrs opingasa omwe amapita kumayendedwe a kufa amapangidwa. Mtsempha wakufa wotsekedwa uli ndi ntchito ziwiri: imodzi ndiyo kupanga zopanda kanthu, ndipo ina ndi yotsogolera.

4. Extrusion Die Forging

Pogwiritsa ntchito njira ya extrusion yopangira kufa, pali mitundu iwiri ya forging, kutsogolo extrusion ndi reverse extrusion. Extrusion die forging imatha kupanga magawo osiyanasiyana opanda kanthu komanso olimba, ndipo imatha kupeza ma forgings olondola kwambiri a geometrical komanso mawonekedwe amkati amkati.

5. Multi-Directional Die Forging

Imapangidwa pamakina opanga ma multidirectional kufa. Kuphatikiza pa kukhomerera koyima ndi jekeseni wa pulagi, makina opangira ma multidirectional kufa alinso ndi ma plungers awiri opingasa. Ejector yake itha kugwiritsidwanso ntchito nkhonya. Kuthamanga kwa ejector ndikwambiri kuposa makina wamba a hydraulic press. Kukhala wamkulu. Popanga ma multidirectional die forging, slider imachita mosinthasintha komanso molumikizana pa chogwiriracho kuchokera kumbali yoyimirira ndi yopingasa, ndipo nkhonya imodzi kapena zingapo zimagwiritsidwa ntchito kuti chitsulo chituluke panja kuchokera pakatikati pa dzenje kuti akwaniritse cholinga chodzaza nkhonya. pakamwa. Palibe ma burrs a forgings apadera pamzere wolekanitsa wa magawo a migolo.

6. Kugawikana Kupanga

Kuti mupange ma forging akuluakulu pamagetsi omwe alipo, njira zopangira ma segmental die forging monga gawo la die forging ndi shim plate die forging zitha kugwiritsidwa ntchito. Mbali ya njira yopangira kufa pang'onopang'ono ndikukonza chidutswa chilichonse, kukonza gawo limodzi panthawi, kotero kuti tonnage yofunikira ya zida ikhoza kukhala yaying'ono kwambiri. Nthawi zambiri, njirayi imatha kugwiritsidwa ntchito pokonza zokopa zazikulu kwambiri pamakina apakatikati a hydraulic.

7. Isothermal Die Forging

Asanayambe kupanga, nkhungu imatenthedwa ndi kutentha kwapang'onopang'ono, ndipo kutentha kwa nkhungu ndi zopanda kanthu kumakhalabe komweko panthawi yonseyi, kotero kuti kuchuluka kwakukulu kwa deformation kungapezeke pansi pa mphamvu yaing'ono yopindika. . Isothermal die forging ndi isothermal superplastic die forging ndizofanana kwambiri, kusiyana kwake ndikuti musanafe kupanga, chopandacho chimafunika kupangidwa ndi superplasticized [i] kuti chikhale ndi mbewu zofananira [ii].

Njira yopangira titanium alloy forging imagwiritsidwa ntchito kwambiri popanga ndege komanso zamlengalenga (Njira ya Isothermal Die Forgingyakhala ikugwiritsidwa ntchito popanga magawo a injini ndi zida zamapangidwe a ndege), ndipo ikukula kwambiri m'magawo a mafakitale monga magalimoto, mphamvu zamagetsi, ndi zombo.

Pakalipano, mtengo wogwiritsira ntchito zipangizo za titaniyamu ndi wokwera kwambiri, ndipo madera ambiri a anthu wamba sanazindikire kukongola kwa titaniyamu. Ndi kupita patsogolo kosalekeza kwa sayansi, kukonzekera kwaukadaulo wa titaniyamu ndi titaniyamu aloyi kudzakhala kosavuta ndipo mtengo wokonza udzakhala wotsika komanso wotsika, ndipo chithumwa cha titaniyamu ndi titaniyamu aloyi aloyi chidzawonetsedwa m'magawo ambiri.

Using extrusion njira ya kufa forging, pali mitundu iwiri ya forging, Forward Extrusion ndi Reverse Extrusion. Extrusion Die Forging imatha kupanga magawo osiyanasiyana opanda kanthu komanso olimba, ndipo imatha kupeza zopangira zolimba kwambiri za geometrical komanso mawonekedwe amkati olimba.

BMT ndi yomwe imadziwika kwambiri popanga premium titaniyamu forging ndi titaniyamu alloy forging yokhala ndi luso lamakina, kukhazikika, kukana dzimbiri, kachulukidwe kochepa komanso kulimba kwambiri. Kupanga ndi kuzindikiritsa kwazinthu za BMT titaniyamu kwagonjetsa zovuta zonse zaukadaulo komanso zovuta zamakina popanga titaniyamu.

Kupanga kwapamwamba kwambiri kwa titaniyamu kumatengera kapangidwe kaukadaulo komanso njira yopita patsogolo pang'onopang'ono. BMT titaniyamu forging ingagwiritsidwe ntchito pamitundu yosiyanasiyana kuchokera kumagulu ang'onoang'ono othandizira mafupa mpaka kukula kwakukulu kwa titaniyamu yopangira ndege.

BMT titaniyamu forgings amagwiritsidwa ntchito m'mafakitale ambiri, monga mlengalenga, uinjiniya wa m'mphepete mwa nyanja, mafuta ndi gasi, masewera, chakudya, galimoto, etc. Kupanga kwathu kwapachaka kumafika matani 10,000.

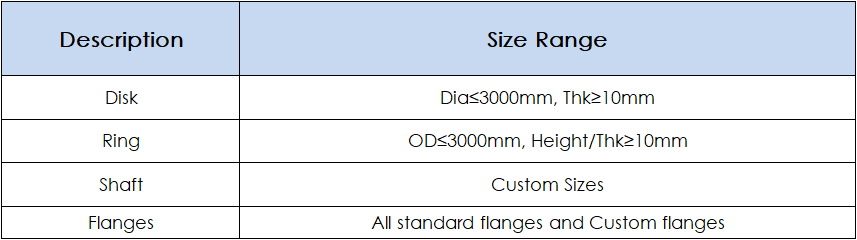

Kukula kwake:

Kupezeka kwa Material Chemical Composition

Kupezeka kwa Material Chemical Composition

Mayeso oyendera:

- Chemical Composition Analysis

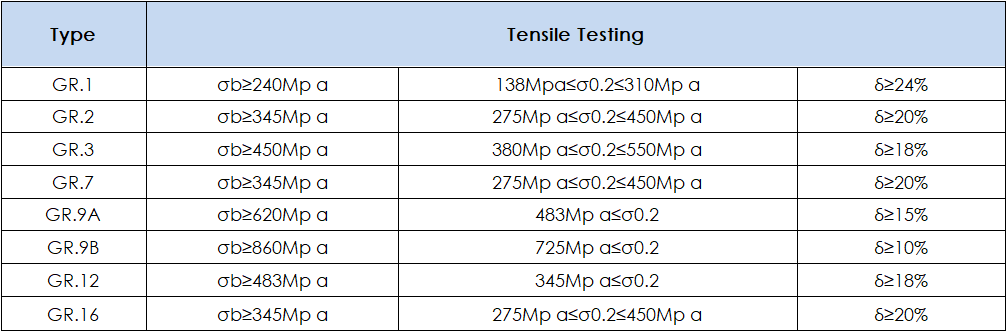

- Mayeso a Katundu Wamakina

- Kuyesa kwa Tensile

- Kuyesa kwa Flaring

- Mayeso a Flattening

- Kupinda Mayeso

- Kuyesa kwa Hydro-Static

- Kuyesa kwa Pneumatic (Kuyesa kuthamanga kwa mpweya pansi pamadzi)

- Chithunzi cha NDT

- Eddy-Current Test

- Mayeso a Ultrasonic

- Kuyesa kwa LDP

- Kuyesa kwa Ferroxyl

Kuchuluka (Kuchuluka ndi Kuchepa Kwambiri kwa Order):Zopanda malire, malinga ndi dongosolo.

Nthawi yotsogolera:Nthawi yotsogolera ndi masiku 30. Komabe, zimatengera kuchuluka kwa dongosolo molingana.

Mayendedwe:Njira yonse yoyendera ndi Nyanja, ndi Air, ndi Express, ndi Sitima, yomwe idzasankhidwa ndi makasitomala.

Kulongedza:

- Chitoliro chimatha kutetezedwa ndi zisoti zapulasitiki kapena makatoni.

- Zosakaniza zonse ziyenera kupakidwa kuti ziteteze malekezero ndi kuyang'ana.

- Zinthu zina zonse zidzadzazidwa ndi ziwiya za thovu ndi zolongedza zapulasitiki zokhudzana ndi plywood.

- Mitengo iliyonse yomwe imagwiritsidwa ntchito popakira iyenera kukhala yoyenera kuteteza kuipitsidwa pokhudzana ndi zida zogwirira ntchito.