Titanium Plate, Mapepala ndi Coil

Njira Yopangira Titanium Plate

Hot Forging Njira yopangira yomwe chitsulo chimawunikidwanso pamwamba pa kutentha.Hot anagubuduza ndondomeko anagubuduza pa kutentha pamwamba recrystallization.Ozizira kugubuduza ndondomeko imene pulasitiki mapindikidwe kutentha ndi otsika kuposa kutentha kuchira.

Annealing: Njira yomwe zitsulo zimatenthedwa pang'onopang'ono mpaka kutentha kwina, kwa nthawi yokwanira, kenako kuzikhazikika (kawirikawiri pang'onopang'ono ndipo nthawi zina zimayendetsedwa) pa mlingo woyenera.

Pickling: Mizidwa mankhwala mu njira yamadzimadzi, monga sulfuric acid, kuchotsa oxides ndi mafilimu ena woonda pa zitsulo pamwamba.

Makhalidwe a mbale ya titaniyamu

1. Titaniyamu seed mbale ndi filimu oxidized pamwamba, amene ali wofanana ndi wabwino kuvala kusamva kulekana ndi wothandizila tsitsi. Kugwiritsiridwa ntchito kwa mbale ya titaniyamu kumapulumutsa cholekanitsa, kumapangitsa kuti mbaleyo ikhale yosavuta kusenda, imathetsa njira yopangira mbewu, ndipo mbale ya titaniyamu imakhala yopepuka kuposa mbale yamkuwa.

2. Moyo wautumiki wa mbale ya titaniyamu ndi yoposa katatu kuposa ya mbale ya copper, yomwe imatha zaka 10 mpaka 20 malinga ndi momwe ntchito ikugwirira ntchito.

3. Electrolytic copper yopangidwa kuchokera ku titaniyamu seed plate imakhala ndi mawonekedwe owoneka bwino a kristalo, yosalala pamwamba komanso yabwino kwambiri.

4. Chifukwa mbale ya titaniyamu sifunikira kukutidwa ndi kupatukana, ikhoza kupeŵa kuipitsidwa kwa electrolyte yamkuwa.

5. Kupititsa patsogolo mphamvu zopangira ndikuchepetsa mtengo wopanga mkuwa wa electrolytic, kuti mukwaniritse bwino chuma.

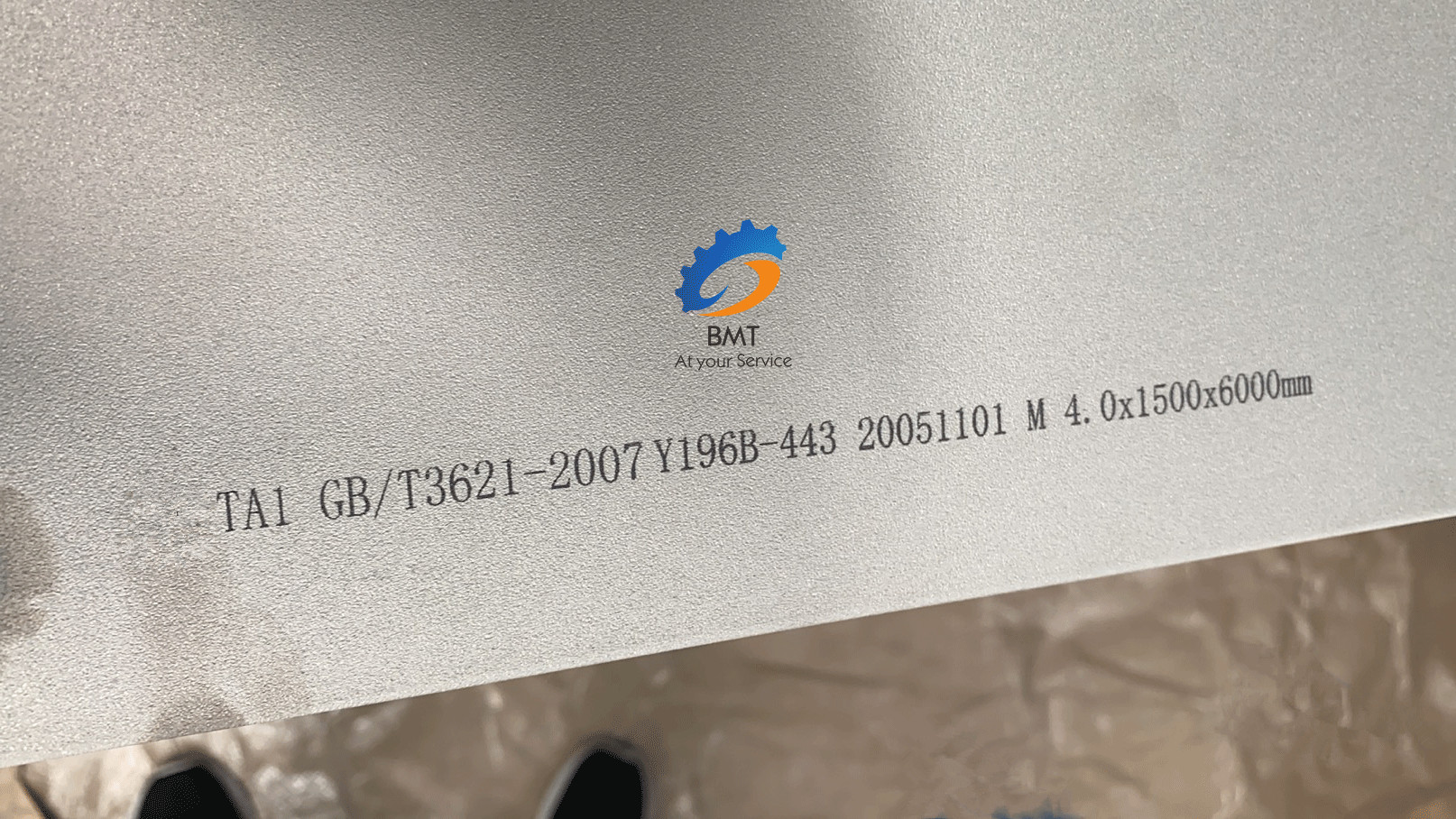

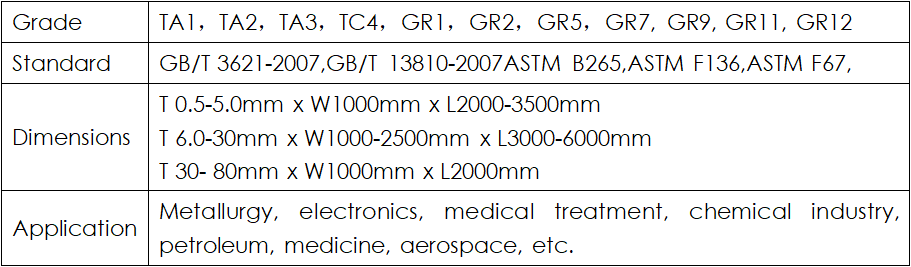

BMT osiyanasiyana pepala titaniyamu ndi mbale amapangidwa motsatira mfundo monga ASTM/ASME B/SB265, ASTM F136, ASTM F67, AMS 4911, ndi AMS4900.

BMT yopanga pachaka ya titaniyamu mapepala ndi paltes ndi 10000 matani, kuphatikizapo 2000 matani PHE (Plate for heat exchanger), ndi 8000 matani ntchito zina. BMT mapepala apamwamba a titaniyamu ndi mbale, kuphatikizapo mapepala ozizira okulungidwa a titaniyamu ndi mbale zotentha za titaniyamu, akutsatiridwa mosamalitsa ndikuyang'anitsitsa zinthu zopangira - siponji ya titaniyamu. BMT imayang'anira njira yonse, monga kusungunuka, kupukuta, kupukuta, kutentha, kuzizira, kutentha kutentha, ndi zina zotero. Timatumiza katundu padziko lonse lapansi ndikukulandirani mwachikondi kuti mugwirizane nafe.

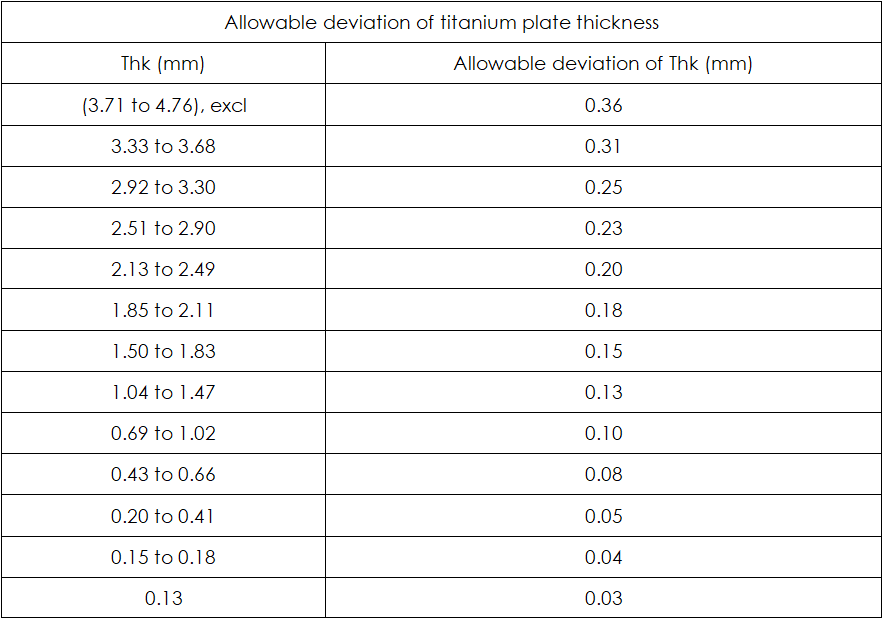

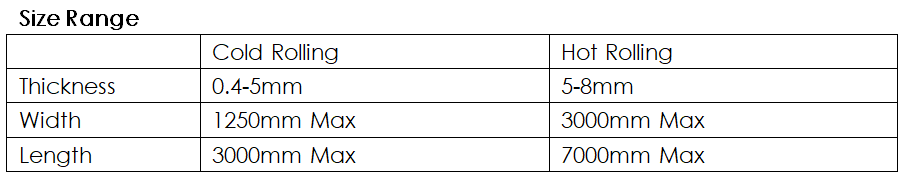

Kupatuka kwa Titanium Plate Makulidwe Kololeka:

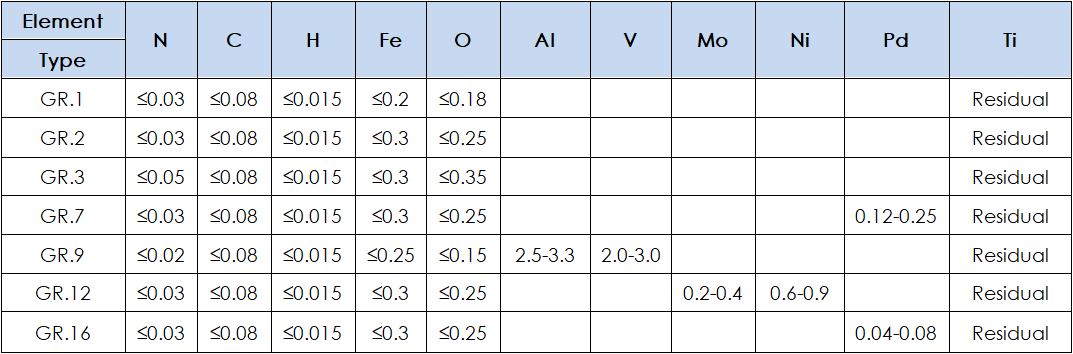

Zomwe Zilipo za Chemical Chemical:

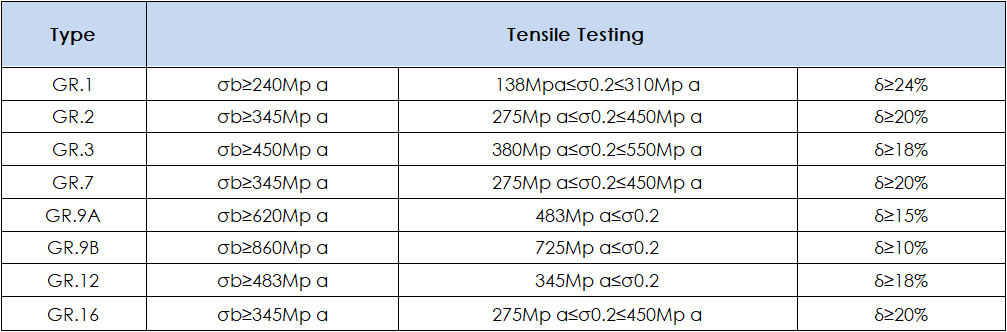

Katundu Wamakina Opezeka:

Mayeso oyendera:

- Chemical Composition Analysis

- Mayeso a Katundu Wamakina

- Kuyesa kwa Tensile

- Kuyesa kwa Flaring

- Mayeso a Flattening

- Kupinda Mayeso

- Kuyesa kwa Hydro-Static

- Kuyesa kwa Pneumatic (Kuyesa kuthamanga kwa mpweya pansi pamadzi)

- Chithunzi cha NDT

- Eddy-Current Test

- Mayeso a Ultrasonic

- Kuyesa kwa LDP

- Kuyesa kwa Ferroxyl

Kuchuluka (Kuchuluka ndi Kuchepa Kwambiri kwa Order):Zopanda malire, malinga ndi dongosolo.

Nthawi yotsogolera:Nthawi yotsogolera ndi masiku 30. Komabe, zimatengera kuchuluka kwa dongosolo molingana.

Mayendedwe:Njira yonse yoyendera ndi Nyanja, ndi Air, ndi Express, ndi Sitima, yomwe idzasankhidwa ndi makasitomala.

Kulongedza:

- Chitoliro chimatha kutetezedwa ndi zisoti zapulasitiki kapena makatoni.

- Zosakaniza zonse ziyenera kupakidwa kuti ziteteze malekezero ndi kuyang'ana.

- Zinthu zina zonse zidzadzazidwa ndi ziwiya za thovu ndi zolongedza zapulasitiki zokhudzana ndi plywood.

- Mitengo iliyonse yomwe imagwiritsidwa ntchito popakira iyenera kukhala yoyenera kuteteza kuipitsidwa pokhudzana ndi zida zogwirira ntchito.