Zinthu Zomwe Zimakhudza Kusokonekera kwa Gawo

- Gawo Kukula

Kukula kokha sikumatsimikizira zovuta za gawolo, koma kungakhale chinthu. Kumbukirani, nthawi zina zigawo zazikuluzikulu zimakhala zovuta kwambiri kusiyana ndi zing'onozing'ono, zovuta kwambiri. Komanso, ganizirani kukula kwa mawonekedwe a munthu aliyense, chifukwa izi zimakhudza kukula kwa chida chodulira chomwe chidzagwiritsidwa ntchito. Chida chokulirapo, chothamanga kwambiri chimatha kuchotsa zinthu mwachangu, kuchepetsa nthawi yopangira makina.

- Part processing

Kuchuluka kwa magwiridwe antchito, kulowererapo ndi kuwunika kofunikira pagawoli kudzakhudzanso zovuta za gawolo. Kutengera ndi geometry, kumaliza ndi kulolerana ndi zina, dongosolo la ntchito litha kukhala lovuta, lowononga nthawi komanso latsatanetsatane. Mwachitsanzo, gawo lovuta lingafunike kukonzanso kangapo komanso kuchitapo kanthu pamanja. Nthawi zina, makina a 5 axis kapena mphero akhoza kukhala makina oyenerera kwambiri, mwachitsanzo, ngati ali otsika mtengo kupanga kapena amafuna ndalama zochepa.

- Mbali kulolerana

Kulekerera kwa gawo kungakhudze kusankha kwa makina a CNC omwe amagwiritsidwa ntchito komanso kungakhudze mtengo ndi nthawi yotsogolera. Kulekerera kothekera kumakhudzidwanso ndi zinthu, kuthamanga kwa makina ndi zida. Mwachidule, kupirira kolimba, gawo lanu lidzakwera mtengo kwambiri. Kulekerera kwapamwamba kumalola kulondola kwambiri, koma kungaphatikizepo njira zowonjezera, ntchito, ndi zida ndi makina, motero zimawonjezera mtengo.

Mitundu ya kumaliza

- Kuphulika kwa Mikanda

Kuphulika kwa Bead kumaphatikizapo kuchotsedwa kwa ma depositi aliwonse a pamwamba kapena zolakwika pa gawo kuti likhale lofanana, losalala. Mikanda yooneka ngati bwalo imatsimikizira kutha kofanana ndipo nthawi zambiri imagwiritsidwa ntchito popereka matt. Mikanda yowoneka bwino imatha kugwiritsidwanso ntchito ngati satin kapena kumalizidwa kosalala.

- Anodized amatha

Zomaliza za anodized zimapereka zokutira zosagwirizana ndi kuvala, zomwe nthawi zambiri zimapezeka mumitundu ingapo. Anodizing nthawi zambiri imaonekera, ndipo wosanjikiza nthawi zambiri amakhala woonda kotero onetsetsani kuti mukuganizira zizindikiro za CNC Machine pamtunda.

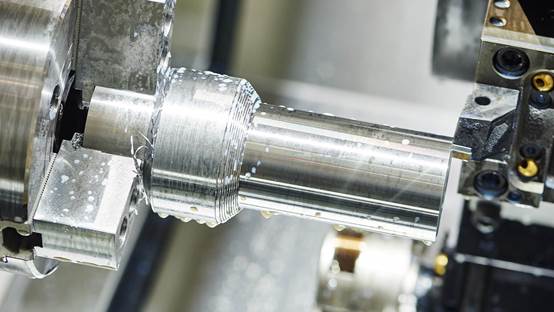

- Monga makina

Kutsirizitsa kwina kudzasiya kuuma kwa pamwamba pamene chidutswacho chimapangidwa ndi makina. Kuvuta kwenikweni kwa ntchito kumatsimikiziridwa pogwiritsa ntchito mtengo wa Ra. Nthawi zambiri roughness pamwamba kwa CNC machined mbali ndi Ra 1.6-3.2µm.

Malipoti a CMM Inspection

Kodi lipoti la CMM ndi chiyani ndipo ndikufunika?

Kuwunika kwa Coordinate Measurement Machine (CMM) kumaphatikizapo kugwiritsa ntchito makina oyezera ogwirizana kuti ayang'ane kukula kwa gawo kuti atsimikizire ngati gawolo likukwaniritsa zofunikira zololera. Makina Oyezera Ogwirizanitsa amagwiritsidwa ntchito poyeza mtundu ndi mawonekedwe a chinthu.

Kuwunika kwa CMM kudzafunika kuyeza zigawo zovuta kwambiri kuti zitsimikizire kuti zikugwirizana ndi zomwe zafotokozedwa. Nthawi zambiri amaphatikizidwa m'magawo olondola kwambiri omwe amafunikira kuwongolera komanso kulondola kwambiri. Panthawiyi, zotsirizira zosalala zidzawunikidwanso kuti zitsimikizire kuti ndizolondola pazojambula ndi mapangidwe.

CMM imagwira ntchito pogwiritsa ntchito kafukufuku yemwe amayesa mfundo zachindunji. 3 nkhwangwa zimapanga makina olumikizirana. Dongosolo lina ndi gawo logwirizanitsa dongosolo, pomwe nkhwangwa 3 zimagwirizana / zimagwirizana ndi mawonekedwe ndi kuchuluka kwa ntchitoyo.

Ubwino wa CMM Inspection

Kuwunika kwa CMM kudzachitika ngati pakufunika, ndipo nthawi zina kumakhala kovomerezeka. Malipoti a CMM Inspection amatha kusunga nthawi ndikuchepetsa ndalama zochulukirapo powonetsetsa kuti gawolo lapangidwa molondola pamapangidwewo. Izi zimatsimikizira kuti palibe chomwe chasiyidwa mwangozi ndipo zokhota zilizonse kuchokera pamapangidwe kapena zolakwika zimapezeka musanatumize.

Malingana ndi makampani, zopotoka kuchokera kuzinthu zowonongeka zingakhale zoopsa (Mwachitsanzo, makampani azachipatala, kapena makampani oyendetsa ndege.) Kufufuza komaliza kumeneku kungathe kupereka chitsimikiziro gawolo lisanasainidwe ndikuperekedwa kwa kasitomala.