Kuwotcherera kwa Titanium Alloy

Ndi gawo limodzi la aloyi wopangidwa ndi β-phase solid solution.Popanda chithandizo cha kutentha, chimakhala ndi mphamvu zambiri.Pambuyo kuzimitsa ndi ukalamba, aloyi ndi patsogolo.Kulimbitsa sitepe imodzi, mphamvu ya kutentha kwa chipinda imatha kufika 1372 ~ 1666 MPa;Koma matenthedwe bata ndi osauka, sayenera kugwiritsidwa ntchito pa kutentha.

Ndi aloyi biphasic, ali ndi katundu wabwino mabuku, kukhazikika bwino dongosolo, kulimba bwino, plasticity ndi mkulu kutentha mapindikidwe katundu, kungakhale bwino kwa kutentha kuthamanga processing, akhoza kuzimitsidwa, kukalamba kulimbikitsa aloyi.Mphamvu pambuyo mankhwala kutentha pafupifupi 50% ~ 100% apamwamba kuposa pambuyo annealing;Kutentha kwakukulu kwamphamvu, kumatha kugwira ntchito mu kutentha kwa 400 ℃ ~ 500 ℃ kwa nthawi yayitali, kukhazikika kwake kwamafuta kumakhala kotsika kuposa α titaniyamu aloyi.

Pakati pa zitsulo zitatu za titaniyamu, zomwe zimagwiritsidwa ntchito kwambiri ndi α titanium alloy ndi α + β titanium alloy;Ntchito yodula ya α titanium alloy ndiyo yabwino kwambiri, yotsatiridwa ndi α + β titanium alloy, ndipo β titanium alloy ndiyo yoyipa kwambiri.α titanium alloy code ya TA, β titanium alloy code ya TB, α+β titanium alloy code ya TC.

Titaniyamu aloyi akhoza kugawidwa mu kutentha kugonjetsedwa aloyi, mkulu mphamvu aloyi, dzimbiri zosagwira aloyi (titaniyamu - molybdenum, titaniyamu - palladium aloyi, etc.), otsika kutentha aloyi ndi ntchito aloyi wapadera (titaniyamu - chitsulo hydrogen yosungirako zinthu ndi titaniyamu - nickel kukumbukira aloyi).Mapangidwe ndi katundu wa ma aloyi wamba akuwonetsedwa patebulo.

Mitundu yosiyanasiyana ya magawo ndi ma microstructure a titaniyamu omwe amathiridwa ndi kutentha amatha kupezeka posintha njira yochizira kutentha.Nthawi zambiri amakhulupirira kuti zida zabwino zofananira zimakhala ndi pulasitiki yabwino, kukhazikika kwamafuta komanso mphamvu zotopa.Mapangidwe a spiculate amakhala olimba kwambiri, mphamvu zokwawa komanso kulimba kwa fracture.Minofu yosakanikirana ya equiaxial ndi singano imakhala ndi mawonekedwe abwinoko.Titaniyamu ndi mtundu watsopano wachitsulo, ntchito ya titaniyamu ikugwirizana ndi zomwe zili mu carbon, nayitrogeni, haidrojeni, mpweya ndi zonyansa zina, zonyansa zonyansa za titaniyamu siziposa 0,1%, koma mphamvu zake ndizochepa, pulasitiki yapamwamba kwambiri. .

The katundu wa 99.5% mafakitale koyera titaniyamu ndi motere: kachulukidwe ρ=4.5g/ kiyubiki masentimita, malo osungunuka 1725 ℃, matenthedwe matenthedwe λ=15.24W/(mK), kumakoka mphamvu σb=539MPa, elongation δ=25%, gawo kuchepa ψ=25%, zotanuka modulus E=1.078×105MPa, kuuma HB195.Kachulukidwe wa titaniyamu aloyi zambiri za 4.51g/ kiyubiki centimita, 60% okha zitsulo, mphamvu ya titaniyamu koyera ndi pafupi mphamvu ya chitsulo wamba, ena mkulu mphamvu titaniyamu aloyi kuposa mphamvu ya aloyi ambiri structural zitsulo.Choncho, mphamvu yeniyeni (mphamvu / kachulukidwe) ya titaniyamu alloy ndi yaikulu kwambiri kuposa yazitsulo zina zazitsulo, monga momwe tawonetsera mu Table 7-1.Ikhoza kupanga magawo ndi magawo omwe ali ndi mphamvu zambiri za unit, kukhazikika kwabwino komanso kulemera kopepuka.Pakadali pano, ma aloyi a titaniyamu amagwiritsidwa ntchito pazigawo za injini, mafupa, khungu, zomangira ndi zida zofikira.

Titumizireni uthenga wanu:

-

Aluminium CNC Machining Parts

-

Kupanga Chitsulo cha Aluminium

-

Axis High Precision CNC Machining Parts

-

Zida Zopangidwa ndi CNC ku Italy

-

CNC Machining Aluminium Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

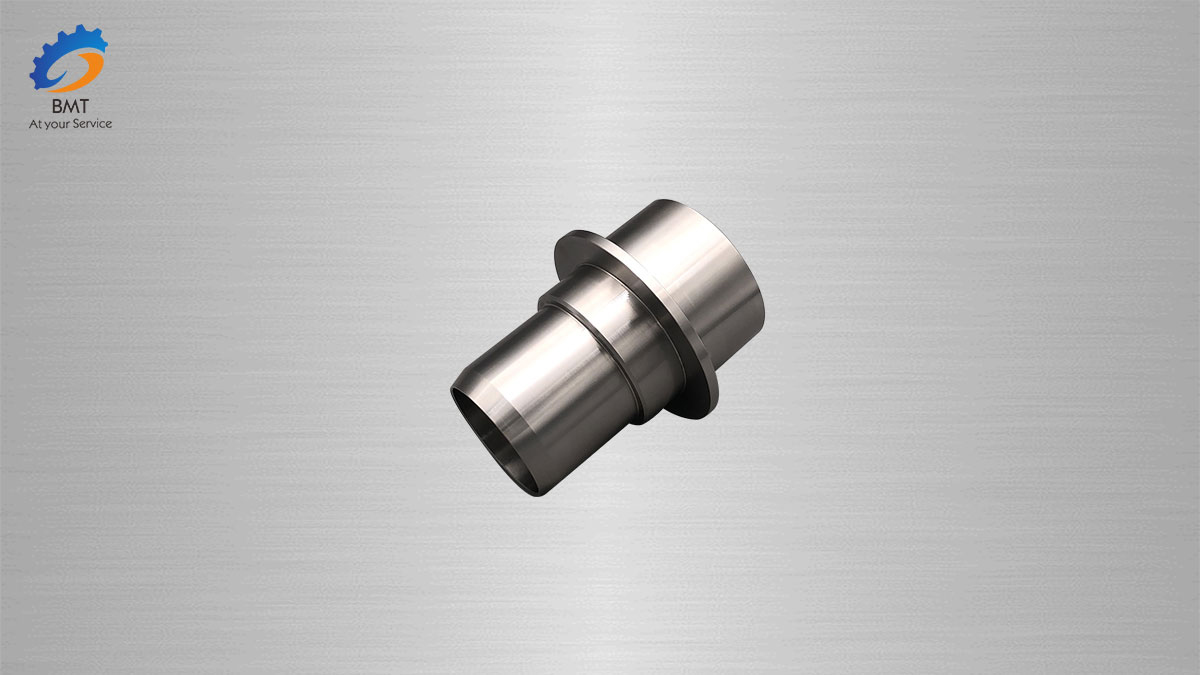

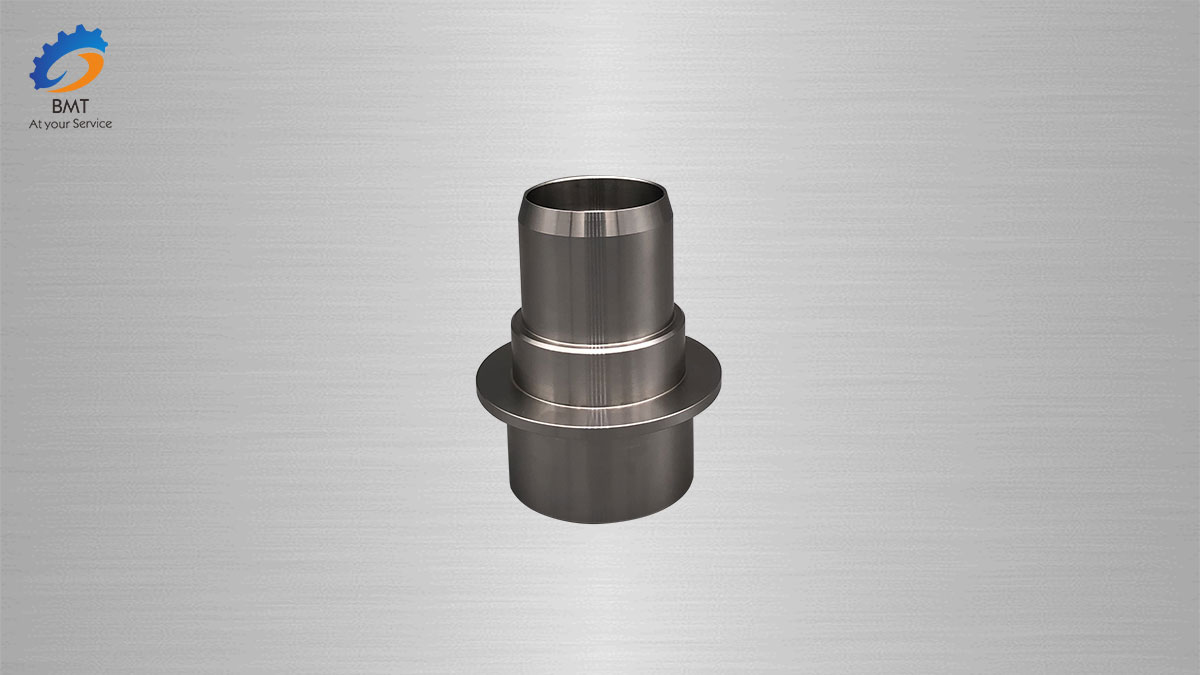

Zida za Titanium ndi Titanium Alloy

-

Titaniyamu ndi Titanium Alloy Forgings

-

Titaniyamu ndi Titanium Alloy Waya

-

Mipiringidzo ya Titaniyamu

-

Titaniyamu Mipope/Machubu Opanda Msokonezo

-

Titaniyamu Welded mapaipi/machubu