Cholakwika pa Guiderail

Kuwongolera ndi chimodzi mwa zolakwika za zida zamakina, cholakwika mu chida cha makina, njanji yowongolera ndiyomwe imayang'anira gawo la zida zamakina, komanso kulondola kwa slideway, kumawoneka ngati vuto, kotero malo a magawo mu makina. kulakwitsa kwa chida kudzachitika ndipo kulondola kwa makina kudzakhudzidwa. Nthawi zambiri, cholakwa chowongolera makamaka kukhalapo kwa digiri yofananira ya kupotoza, chishalo, cholakwika cha ng'oma, cholakwika chopingasa chowongoka, cholakwika chowongoka cha njira zingapo, monga kupotoza kofananira kumatanthawuza njanji yakutsogolo ndi kumbuyo kwa kalozera kuchokera kugawo lofanana; Cholakwika cha chishalo ndi njanji yolowera kumbuyo, njanji yolondolera ndikulakwitsa kwa ng'oma, zonsezi ndi mtundu wa kusintha kwa mawonekedwe a njanji; Ndipo cholakwika chowongoka chowongoka ndi chowongoka ndi njanji yopindika yopindika, kupindika kozungulira.

Cholakwika Chain Transmission

Kufala unyolo wa ntchito yaikulu ndi kulamulira kasinthasintha workpiece ndi chida, mmene pali zambiri kusuntha mbali, ngati zigawozi kuwoneka zolakwika pa kupanga, msonkhano, kapena m'kati ntchito kwambiri kuvala ndi kung'ambika, kotero chiŵerengero. mgwirizano pakati pa chida ndi workpiece idzakhudzidwa, ndipo motero zimakhudza kulondola kwa makina.

Stress Deformation

Mu ndondomeko ya Machining, dongosolo Machining adzakhala mitundu yonse ya mphamvu, monga mphamvu centrifugal, kudula mphamvu ndi zina zotero, izi mphamvu mu galimoto chida, workpiece, jigs ndi ntchito zina wathunthu processing, pa nthawi yomweyo. zimakhudza zigawo zina malo, kuthamanga kwa kayendedwe, zomwe zimapangitsa kuchepa kwa makina olondola. Mwachitsanzo, pamene kudula chida mu ndondomeko Machining amakhudzidwa ndi mphamvu centrifugal, choyambirira kudula kugwedera zidzachitika ndi ntchito ndi zojambulajambula chifukwa ndi mkulu liwiro kugwedera ndi kudula nkhope ya mbali makina adzaoneka cholakwika.

Chida Chamakina, Chida Chodulira Matenthedwe Otentha

Makina opangira zida zamakina amitundu yosiyanasiyana yamasewera othamanga amapangitsa kukangana kothamanga kwambiri pakati pa magawo kapena zigawo ndi mpweya, kenako kutulutsa kutentha kwambiri, ndipo chifukwa cha kutentha kwa bilges kuzizira kumachepetsa chodabwitsa, makina a makina aziwoneka mosiyana. madigiri a matenthedwe matenthedwe ndipo, nawonso, zimakhudza kulondola kwa Machining, chodabwitsa mu chida makina, kudula chida, Workpieces ndizofala kwambiri, pamene pali mapindikidwe matenthedwe a makina chida, bokosi spindle ndi kalozera njanji zikuoneka kuonekera. kupindika, kupindika, kutsogoza zolakwika ndi zolakwika za spindle.

Ndipo pakakhala chida chotentha cha deformation, voliyumu yake imapitilira kusakhazikika mumtundu wina, ndikukonza magawo amakina kukula kosiyanasiyana kudzachitika. Komanso, mapindikidwe matenthedwe workpiece zingakhudze buku la workpiece, ngakhale kusintha kuti osati mwachindunji amakhudza mawonekedwe, koma ngati workpiece ndi mkangano mosagwirizana, kotero mu ndondomeko ya mapindikidwe komanso kungayambitse nkhawa mkati kuchokera mkati, ndi maganizo mkati adzakhala ngati pamwamba zitsulo workpiece excision ndi kugawanso mkati mwa zinthu zakale, kulimbikitsa zaluso kuoneka mapindikidwe zoonekeratu, ndipo pambuyo workpiece mapindikidwe , mbali makina processing mwatsatanetsatane chikhalidwe komanso amachepetsa.

Titumizireni uthenga wanu:

-

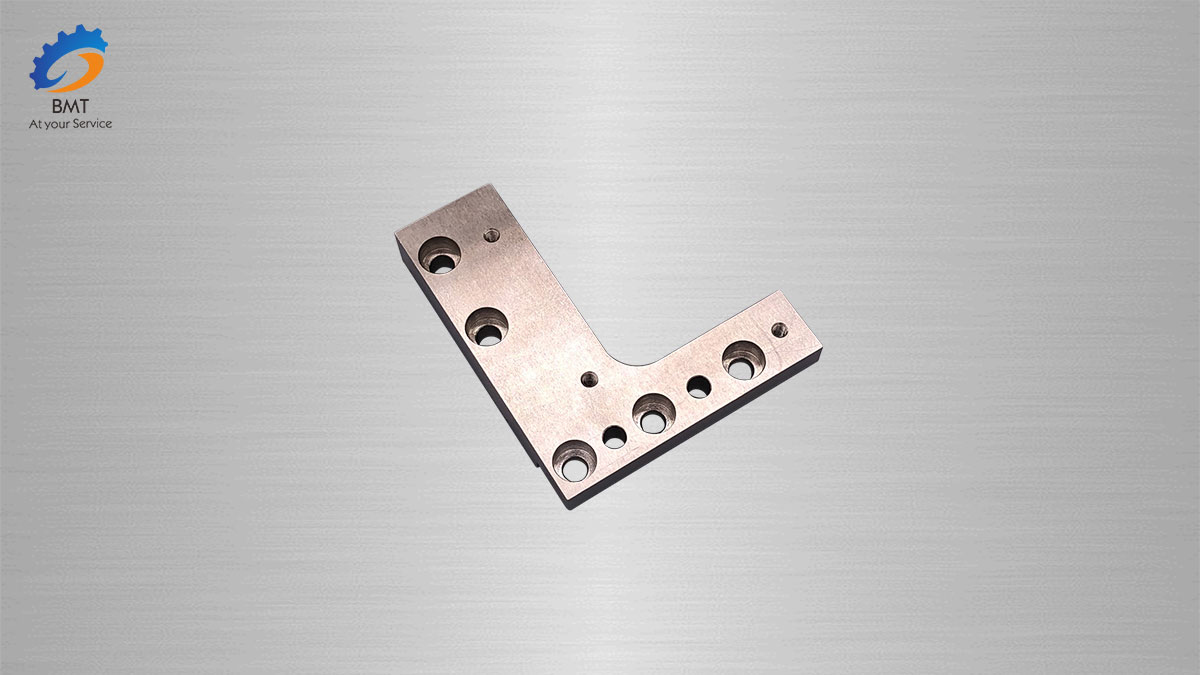

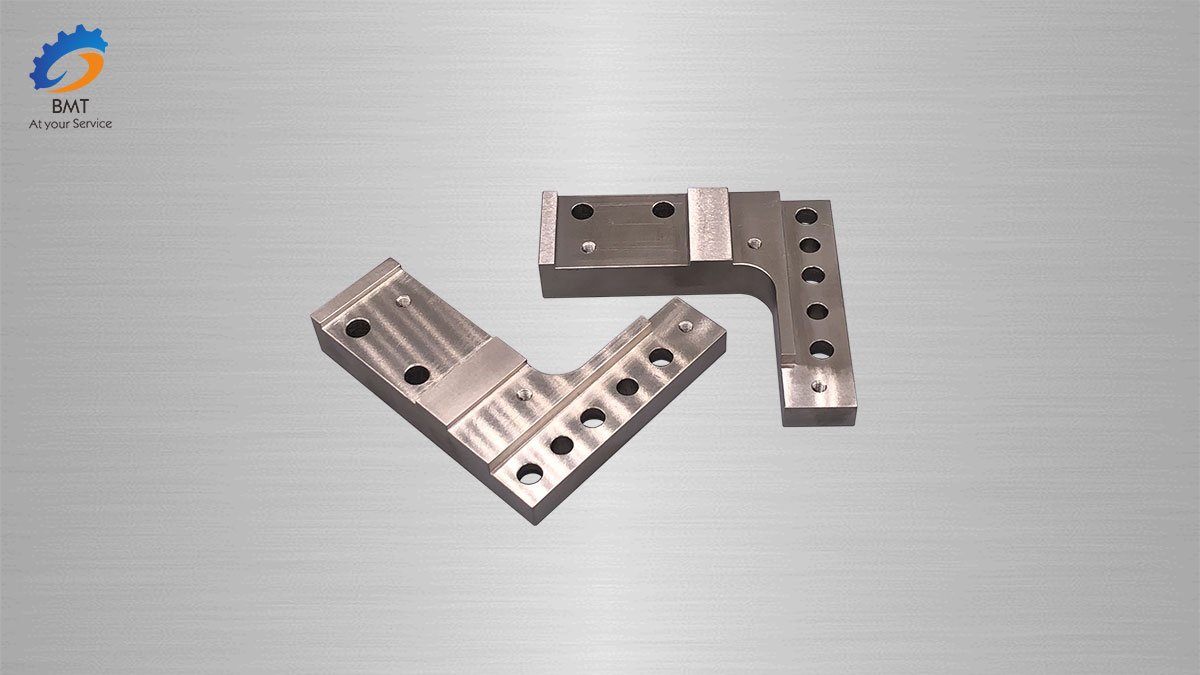

Aluminium CNC Machining Parts

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

Zida Zopangidwa ndi CNC ku Italy

-

CNC Machining Aluminium Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Zida za Titanium ndi Titanium Alloy

-

Titaniyamu ndi Titanium Alloy Forgings

-

Titaniyamu ndi Titanium Alloy Waya

-

Mipiringidzo ya Titaniyamu

-

Titaniyamu Mipope/Machubu Opanda Msokonezo

-

Titaniyamu Welded mapaipi/machubu