Mafunde a Pulse ndi Continuous Wave Modes

Gawo lofunika kwambiri la kuwala kwa micromachining ndikutengera kutentha kudera la gawo lapansi loyandikana ndi zinthu zopangidwa ndi micro-machine.Ma laser amatha kugwira ntchito mu pulsed mode kapena mosalekeza mafunde.Mumayendedwe opitilira mafunde, kutulutsa kwa laser kumakhala kosasintha pakapita nthawi.

Mu pulsed mode, laser linanena bungwe anaikira ang'onoang'ono pulses.Zida za laser za pulsed mode zimapereka ma pulse ndi nthawi yaying'ono yamphamvu ndi mphamvu zokwanira micromachining ya chinthu choperekedwa.Kuthamanga kwakung'ono kumachepetsa kutentha kwa zinthu zozungulira.Kuthamanga kwa laser kumatha kusiyana kutalika kuchokera ku milliseconds kupita ku femtoseconds.

Mphamvu yapamwamba imakhudzana ndi nthawi ya kugunda kwa laser, kotero ma lasers othamanga amatha kukwaniritsa nsonga zapamwamba kuposa mafunde osalekeza.

Kukonzekera kwa laser kumaphatikizapo kuyanjana komwe kumapangitsa kuti gawo lapansi lichotsedwe.Kutengerapo mphamvu komwe kumachitika kumadalira zinthu zakuthupi ndi laser.Mawonekedwe a laser omwe amakhudza zinthu amaphatikizapo mphamvu yapamwamba, kugunda kwamtima, komanso kutalika kwa mafunde.Kuganizira zakuthupi ndikuti chitha kuyamwa mphamvu ya laser kudzera munjira zamatenthedwe ndi/kapena zazithunzi.

Chifukwa chiyani kugunda kwamtima kuli kofunikira?

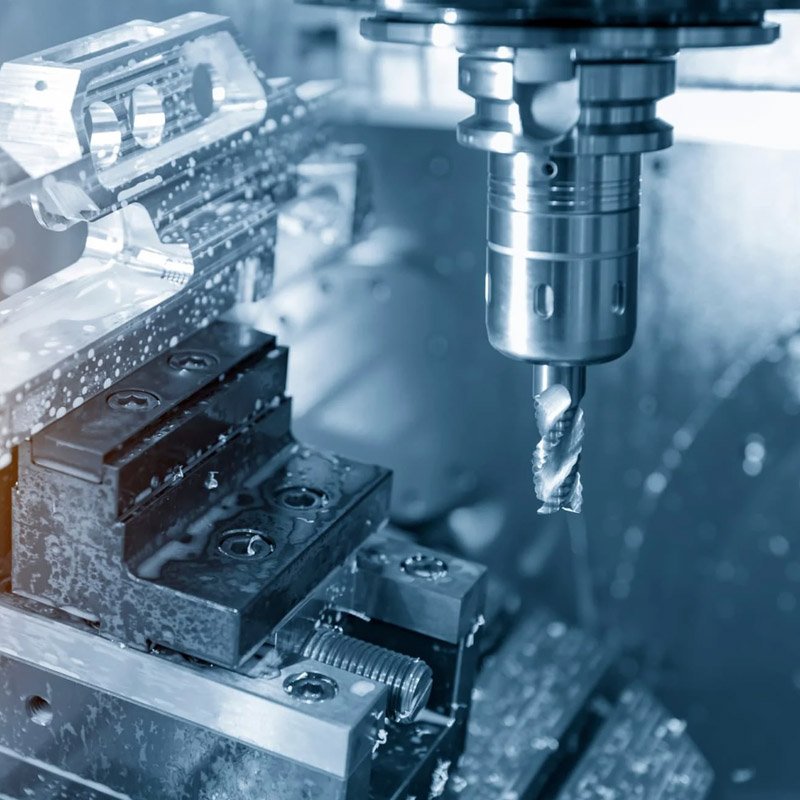

Kudula kwa laser ndikoyera komanso kolondola.Kufunika kopanga zida zazing'ono, zofulumira, zopepuka komanso zotsika mtengo kumafuna ma lasers kuti akwaniritse zovuta.Ma lasers a pulsed amagwiritsidwa ntchito popanga ma micromachining olondola azinthu zosiyanasiyana.Kutha kupanga makulidwe osiyanasiyana a pulse ndiye chinsinsi cha kulondola, kutulutsa, kudalirika komanso kutsika mtengo.

Ma lasers a Nanosecond amagwiritsa ntchito mphamvu zomwezo zomwe zimakhala ndi ziwopsezo zapamwamba zochotsa zinthu motero zimatuluka kwambiri kuposa ma laser a picosecond ndi femtosecond.

Picosecond ndi femtosecond lasers amasungunula zinthu kuti zichotsedwe kudzera munjira ya vaporizing ndikusungunula zinthuzo kuti zitulutse.Kusungunuka kumeneku kungakhudze kulondola ndi khalidwe la makina, monga zinthu zomwe zachotsedwa zimatha kumamatira m'mphepete ndikulimbitsanso.

Kupita patsogolo kwaukadaulo wa laser pulsed kwapangitsa kuti zitheke kugwiritsa ntchito ma micromachining pazida zing'onozing'ono, monga zida zamankhwala, zomwe siziwononga pang'ono pazinthu zozungulira.Ndi kupita patsogolo kofulumira kwa sayansi pankhani ya lasers, ukadaulo wa laser micromachining ndikofunikira.

Njira yopangira makina imatanthawuza njira yonse yopangira zinthu kuchokera kuzinthu zopangira (kapena zomaliza).Kupanga makina, kumaphatikizapo mayendedwe ndi kusungirako zinthu zopangira, kukonzekera kupanga, kupanga zopanda kanthu, kukonza magawo ndi chithandizo cha kutentha, kusonkhanitsa mankhwala, ndi kukonza zolakwika, kujambula ndi kuyika, ndi zina zotero.Mabizinesi amakono amagwiritsa ntchito mfundo ndi njira zamakina opangira makina kuti akonze ndikuwongolera kupanga, ndikuwona njira yopangira ngati njira yopangira yomwe imathandizira komanso zotuluka.

Nthawi yotumiza: Oct-13-2022