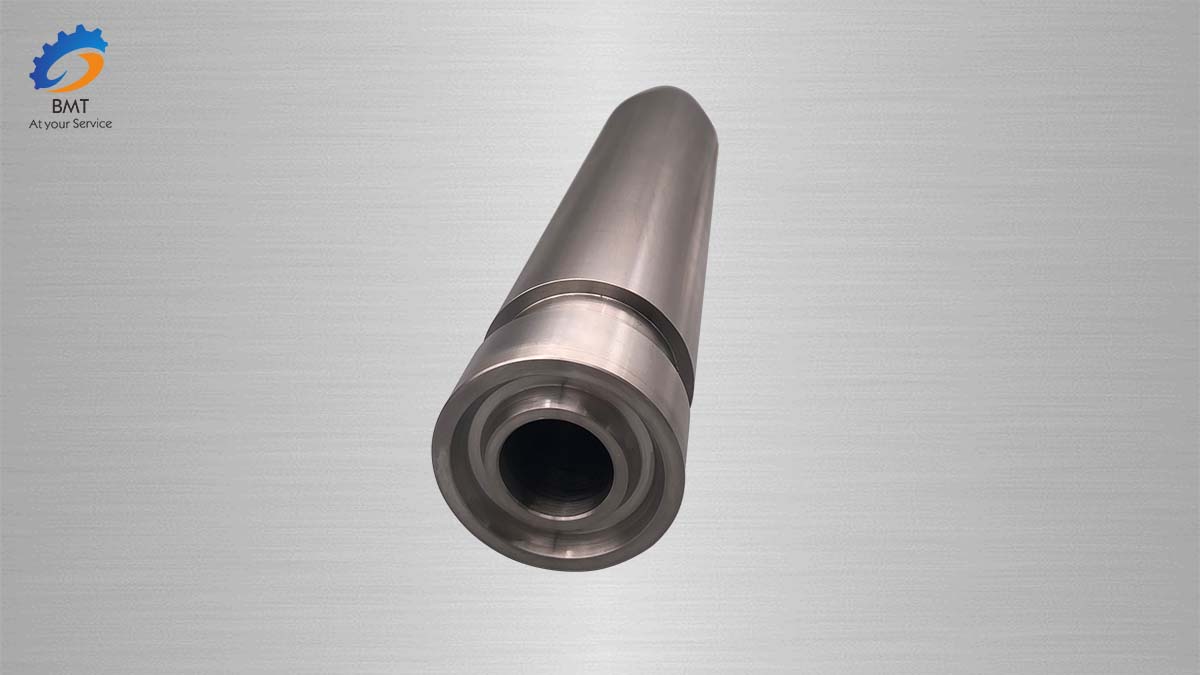

Titanium Alloy CNC Machining

Kusindikiza kwazitsulo za titaniyamu kumafanana kwambiri ndi zitsulo zachitsulo kusiyana ndi zitsulo zopanda chitsulo ndi alloys. Zambiri zamagawo azitsulo za titaniyamu popanga, kupondaponda kwa voliyumu ndi kupondaponda kwamasamba zili pafupi ndi zomwe zikupanga zitsulo. Koma pali zinthu zina zofunika zomwe ziyenera kutsatiridwa mukamasindikiza ma alloys a Chin ndi Chin.

Ngakhale kuti nthawi zambiri amakhulupirira kuti zitsulo za hexagonal zomwe zili mu titaniyamu ndi titaniyamu zimakhala zocheperapo pamene zapunduka, njira zosiyanasiyana zosindikizira zomwe zimagwiritsidwa ntchito popanga zitsulo zina ndizoyeneranso kupanga titaniyamu. Chiŵerengero cha zokolola mpaka malire a mphamvu ndi chimodzi mwa zizindikiro zosonyeza ngati chitsulo chingathe kupirira mapindikidwe apulasitiki. Chiŵerengerochi chikakula kwambiri, chimapangitsa kuti pulasitiki ikhale yolimba kwambiri. Kwa titaniyamu yoyera m'malo ozizira, chiŵerengero ndi 0.72-0.87, poyerekeza ndi 0.6-0.65 ya carbon steel ndi 0.4-0.5 ya chitsulo chosapanga dzimbiri.

Chitani masitampu a voliyumu, kufota kwaulere ndi ntchito zina zokhudzana ndi kukonza magawo akulu akulu ndi zosoweka zazikulu pamalo otentha (pamwamba pa = yS kutentha kwakusintha). Kutentha kosiyanasiyana kwa kupangira ndi kupondaponda kuli pakati pa 850-1150 ° C. Aloyi BT; M0, BT1-0, OT4~0 ndi OT4-1 ali ndi pulasitiki yokhutiritsa m'malo ozizira. Chifukwa chake, magawo opangidwa ndi ma aloyiwa nthawi zambiri amapangidwa ndi zotsekeka zapakatikati popanda kutenthetsa ndi kupondaponda. Pamene titaniyamu aloyi ozizira pulasitiki wopunduka, mosasamala kanthu kapangidwe ake mankhwala ndi makina katundu, mphamvu adzakhala bwino kwambiri, ndipo plasticity adzakhala lofanana kuchepetsedwa. Pachifukwa ichi, chithandizo cha annealing pakati pa njira chiyenera kuchitidwa.

Kuvala kwa groove popanga ma aloyi a titaniyamu ndiko kuvala kwapambuyo kumbuyo ndi kutsogolo molunjika kukuya kwa kudula, komwe nthawi zambiri kumachitika chifukwa cha kusanjikiza kowumitsidwa komwe kumasiyidwa ndi kukonzanso koyambirira. The mankhwala anachita ndi kufalikira kwa chida ndi workpiece zakuthupi pa processing kutentha oposa 800 °C ndi chimodzi mwa zifukwa mapangidwe poyambira kuvala. Chifukwa pakupanga makina, mamolekyu a titaniyamu a workpiece amadziunjikira kutsogolo kwa tsamba ndipo "amawotcherera" pamphepete mwa tsamba pansi pa kuthamanga kwambiri ndi kutentha kwakukulu, kupanga m'mphepete mwake. Pamene m'mphepete mwake mumachotsa pamphepete, chophimba cha carbide choyikapo chimachotsedwa.

Chifukwa cha kukana kutentha kwa titaniyamu, kuziziritsa ndikofunikira pamakina opanga makina. Cholinga cha kuziziritsa ndi kuteteza m'mphepete ndi chida pamwamba pa kutentha kwambiri. Gwiritsani ntchito zoziziritsa kukhosi kuti mutulutse chip bwino mukamachita mphero komanso mphero zakumaso, matumba kapena poyambira. Podula zitsulo za titaniyamu, tchipisi zimakhala zosavuta kumamatira pamphepete, zomwe zimapangitsa kuti mzere wotsatira wodula mphero udulirenso tchipisi, nthawi zambiri zimapangitsa kuti mzere wa m'mphepete ukhale chip.

Chipinda chilichonse chimakhala ndi bowo/jakisoni wake wozizirira kuti athane ndi vutoli ndikuwongolera magwiridwe antchito am'mphepete mwake. Njira ina yabwino kwambiri ndi mabowo oziziritsa a ulusi. Odula mphero zazitali amakhala ndi zoyika zambiri. Kupaka zoziziritsa kukhosi pabowo lililonse kumafuna mphamvu ya mpope yayikulu komanso kukakamiza. Kumbali inayi, imatha kulumikiza mabowo osafunikira ngati pakufunika, potero kukulitsa kuyenda kumabowo omwe akufunika.

Titumizireni uthenga wanu:

-

Aluminium CNC Machining Parts

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

Zida Zopangidwa ndi CNC ku Italy

-

CNC Machining Aluminium Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Zida za Titanium ndi Titanium Alloy

-

Titaniyamu ndi Titanium Alloy Forgings

-

Titaniyamu ndi Titanium Alloy Waya

-

Mipiringidzo ya Titaniyamu

-

Titaniyamu Mipope/Machubu Opanda Msokonezo

-

Titaniyamu Welded mapaipi/machubu