CNC High Precision Machining Parts

M'makampani opanga zinthu masiku ano, kulondola komanso kuchita bwino ndikofunikira kuti mabizinesi azikhala opikisana.Kufunika kwa magawo apamwamba, olondola nthawi zonse, komanso opangidwa mwachangu kwapangitsa kuti pakhale umisiri wotsogola wamakina.Mwa iwo,CNC Machiningchikuwonekera ngati chosintha masewera chomwe chimasintha momwe timafikira kupanga zolondola.CNC (Computer Numerical Control) Machining ndi ukadaulo wapamwamba kwambiri womwe umagwiritsa ntchito mapulogalamu apakompyuta kuwongolera makina, kuwonetsetsa kuti zotsatira zake ndi zolondola komanso zobwerezabwereza.Mosiyana ndi machitidwe opangira makina, omwe amadalira kwambiri ntchito yamanja ndi kulowererapo kwa anthu, CNC Machining imathandizira kupanga, kupereka kulondola kowonjezereka, kuchepetsa zolakwika za anthu, komanso kuchuluka kwa zokolola.

Mtima wa CNC Machining uli mu kuthekera kwake kusintha kapangidwe ka digito, kopangidwa pogwiritsa ntchito mapulogalamu apadera, kukhala zenizeni zenizeni.Mapangidwe ovuta, mawonekedwe ovuta, ndi miyeso yovuta yomwe poyamba inali yovuta kukwaniritsa ndi njira zachikhalidwe tsopano ikukwaniritsidwa mosavuta ndi CNC Machining.Mwa kuwongolera ndendende kayendedwe kazida zodulira, makina a CNC amatha kupanga magawo olondola osayerekezeka, kulolerana kolimba, komanso nthawi yosinthira mwachangu.Chimodzi mwazabwino zazikulu za CNC Machining ndi kusinthasintha kwake kudutsa zida zambiri.Kaya zitsulo zake, mapulasitiki, matabwa, kapena composites, CNC Machining amatha kudula, mphero, kubowola, ndi kupanga zinthu zosiyanasiyana.Kusinthasintha kumeneku kumapangitsa kukhala kosankha kwa mafakitale monga zakuthambo, zamagalimoto, zamankhwala, zamagetsi, ndi ena ambiri, komwe kutsimikizika kwenikweni ndi kumaliza kwapamwamba ndikofunikira.

Kuphatikiza apo, CNC Machining imadzitamandira bwino kwambiri, imalola opanga kukhathamiritsa njira zawo zopangira ndikuchepetsa mtengo.Makina opangira makina opangidwa ndi CNC Machining amathetsa kufunika kokhazikitsa pamanja ndikuwunika kosalekeza, kulola ogwiritsa ntchito kuyang'ana ntchito zina pomwe makinawo akugwira ntchito pawokha.Kuchita bwino kumeneku kumathandizira kwambiri kupanga, zomwe zimapangitsa kuti nthawi yotsogolera ikhale yocheperako komanso kukhutitsidwa kwamakasitomala.Kupitilirakupangidwa bwino kwa gawo, CNC Machining imapereka zabwino zambiri.Imapatsa mphamvu opanga kuwonetsa mwachangu, kubwereza mapangidwe mosavutikira, ndikusintha kuti zigwirizane ndi zomwe msika ukufunikira mosavuta.Pogwiritsa ntchito mapulogalamu apamwamba, makina a CNC amatha kutsanzira njira zopangira, kuzindikira zolakwika zomwe zingatheke, ndikuwongolera njira zothandizira, zomwe zimapangitsa kuti pakhale ndalama zambiri komanso kusunga zinthu.

Kuphatikiza apo, CNC Machining imalimbikitsa kukhazikika mwa kuchepetsa zinyalala komanso kukulitsa kugwiritsa ntchito zinthu.Pozindikira molondola zakuya ndi kayendedwe ka zida,CNC makinakuchepetsa kwambiri zinyalala zakuthupi poyerekeza ndi njira zachikhalidwe.Kuphatikiza apo, kuthekera kogwiritsa ntchito zinyalala ndi zotsalira pazinthu zina kumathandizira kuti pakhale njira yokhazikika yopangira.Zikafika pa CNC Machining, kulondola, kuchita bwino, kusinthasintha, komanso kusasunthika ndizomwe zimayambitsa kutchuka kwake pamakampani opanga.Mwa kuphatikiza luso lamakono lamakono ndi luso la ogwira ntchito aluso, CNC Machining yasintha momwe timafikira kupanga magawo ovuta, prototyping, ndi kupitirira.

Mu conKuphatikiza, CNC Machining yatuluka ngati ukadaulo wosintha masewera, kukonzanso mawonekedwekupangamalo.Kulondola kwake kosayerekezeka, kuthekera kwazinthu zosunthika, komanso njira zopangira zotsika mtengo zimapangitsa kuti ikhale chida chamtengo wapatali m'mafakitale padziko lonse lapansi.Pokumbatira CNC Machining, mabizinesi amatha kukwaniritsa zomwe zikuchulukirachulukira zamtundu, liwiro, komanso kulondola, kuwonetsetsa kuti akuchita bwino pamsika wamakono wampikisano.

Titumizireni uthenga wanu:

-

Axis High Precision CNC Machining Parts

-

Zida za Titanium ndi Titanium Alloy

-

Titaniyamu ndi Titanium Alloy Forgings

-

Titaniyamu ndi Titanium Alloy Waya

-

Mipiringidzo ya Titaniyamu

-

Titaniyamu Mipope/Machubu Opanda Msokonezo

-

Titaniyamu Welded mapaipi/machubu

-

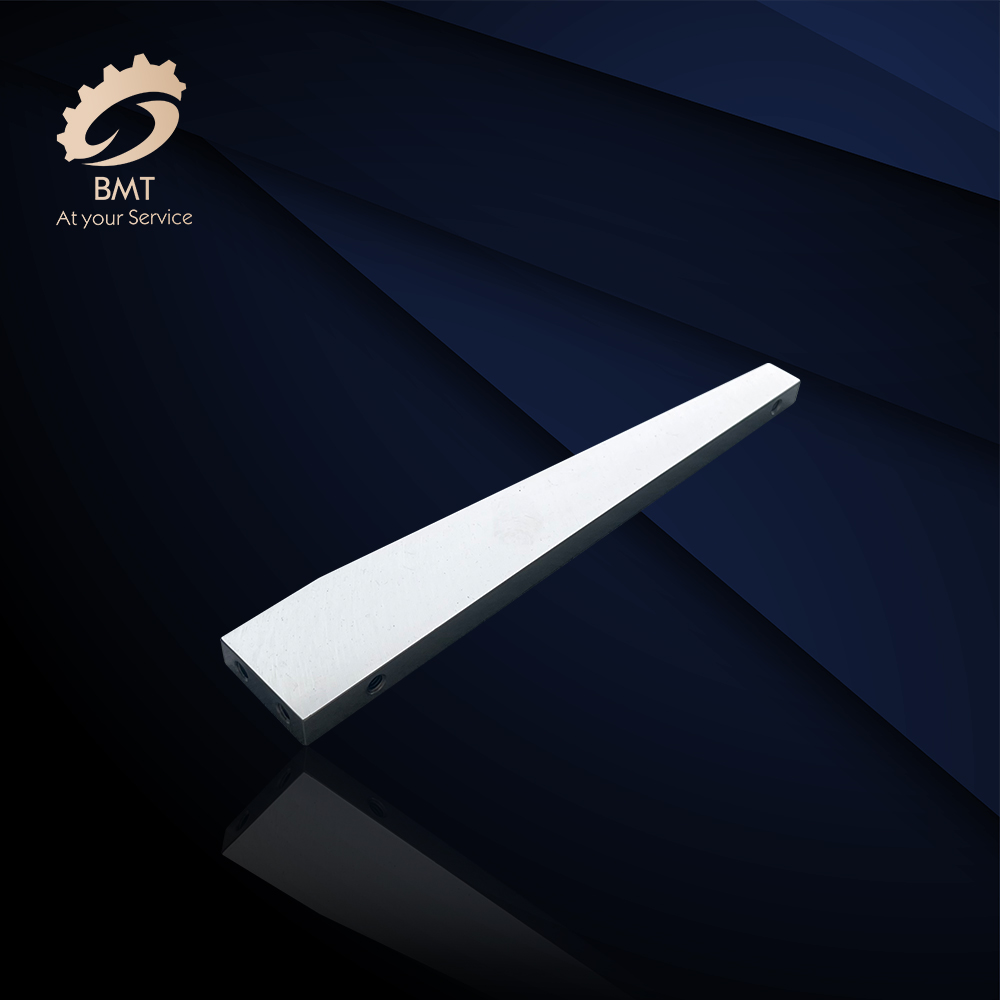

Aluminium CNC Machining Parts

-

Auto Parts Machining

-

Zigawo Zamagalimoto za CNC

-

Zithunzi za CNC Machined Components

-

Kupanga Chitsulo cha Aluminium

-

Makampani Agalimoto

-

Kupera Kwapakati

-

Ubwino wa CNC Machining

-

CNC Machining Aluminium Parts