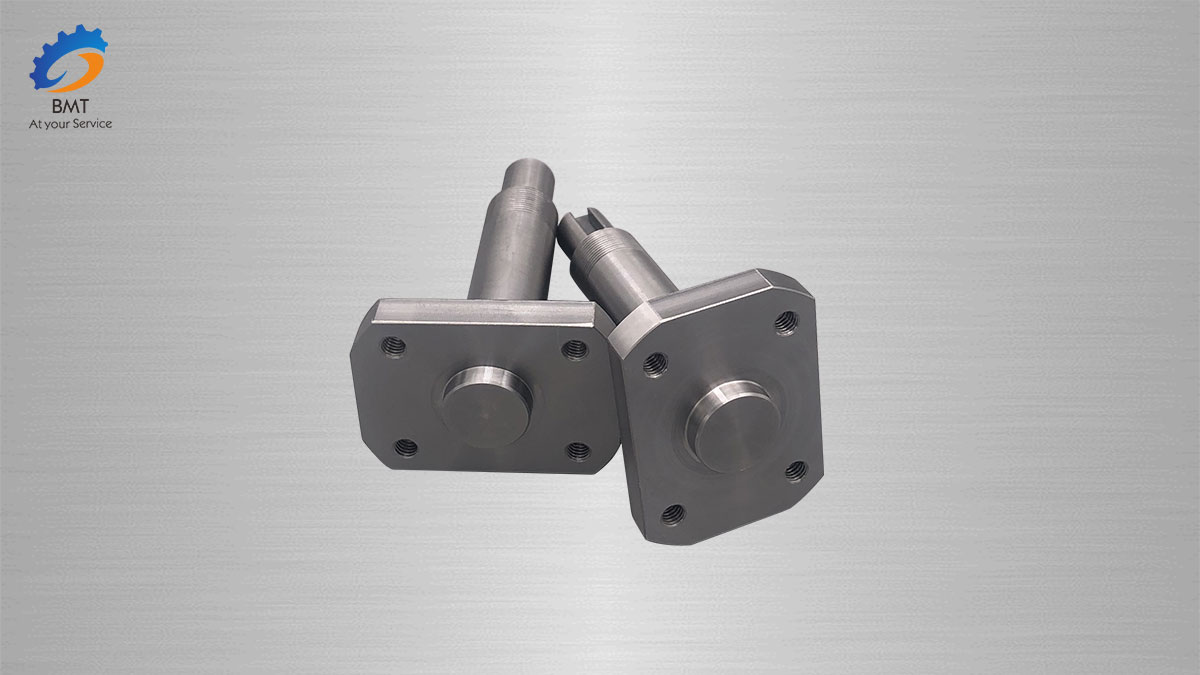

Titanium Machining Zovuta

(1) Deformation coefficient ndi yaying'ono:

Ichi ndi chinthu chodziwikiratu pakupanga zida za titaniyamu aloyi.Pakudula, malo olumikizana pakati pa chip ndi nkhope yowongoka ndi yayikulu kwambiri, ndipo kugunda kwa chip pankhope ya chida ndi yayikulu kuposa yazinthu zonse.Kuyenda kwa nthawi yayitali koteroko kumayambitsa kuvala kwa zida zazikulu, ndipo Kukangana kumachitikanso pakuyenda, komwe kumawonjezera kutentha kwa chida.

(2) Kutentha kwakukulu:

Kumbali imodzi, kagawo kakang'ono ka deformation komwe tatchulidwa pamwambapa kadzatsogolera ku gawo la kutentha.Mbali yaikulu ya kutentha kwapamwamba kwambiri mu titaniyamu alloy kudula ndondomeko ndikuti matenthedwe a titaniyamu a aloyi ndi ochepa kwambiri, ndipo kutalika kwa kukhudzana pakati pa chip ndi nkhope yopangira chida ndi yochepa.

Mothandizidwa ndi zinthu izi, kutentha komwe kumapangidwa panthawi yodula ndikovuta kufalitsa, ndipo makamaka kumaunjikira pafupi ndi nsonga ya chida, zomwe zimapangitsa kuti kutentha kwa m'deralo kukhale kokwera kwambiri.

(3) The matenthedwe madutsidwe aloyi titaniyamu ndi otsika kwambiri:

Kutentha kopangidwa ndi kudula sikutha mosavuta.Kutembenuza kwa titaniyamu alloy ndi njira ya kupsinjika kwakukulu ndi kupsyinjika kwakukulu, komwe kungapangitse kutentha kwakukulu, ndipo kutentha kwakukulu komwe kumapangidwa panthawi yokonza sikungathe kufalitsidwa bwino.Patsamba, kutentha kumakwera kwambiri, tsambalo limafewetsa, ndipo kuvala kwa zida kumathamanga.

Mphamvu zenizeni za titaniyamu alloy ndizokwera kwambiri pakati pa zida zachitsulo.Mphamvu yake ikufanana ndi yachitsulo, koma kulemera kwake ndi 57% yokha ya chitsulo.Kuphatikiza apo, ma aloyi a titaniyamu amakhala ndi mphamvu yokoka yaying'ono, mphamvu yokoka yayikulu, kukhazikika kwamafuta abwino komanso kukana dzimbiri, koma zida za titaniyamu ndizovuta kuzidula komanso kukhala ndi magwiridwe antchito ochepa.Chifukwa chake, momwe mungagonjetsere zovuta komanso kutsika kwamphamvu kwa titaniyamu alloy processing nthawi zonse lakhala vuto lofunika kuthetsedwa.

Titumizireni uthenga wanu:

-

Aluminium CNC Machining Parts

-

Kupanga Chitsulo cha Aluminium

-

Axis High Precision CNC Machining Parts

-

Zida Zopangidwa ndi CNC ku Italy

-

CNC Machining Aluminium Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Zida za Titanium ndi Titanium Alloy

-

Titaniyamu ndi Titanium Alloy Forgings

-

Titaniyamu ndi Titanium Alloy Waya

-

Mipiringidzo ya Titaniyamu

-

Titaniyamu Mipope/Machubu Opanda Msokonezo

-

Titaniyamu Welded mapaipi/machubu